| February, 2002

G'day,

Harrigami sailing and trailing photos attached.

On the trailer. Mast goes under the cockpit, sits on

the lee hull. Boom could go on top, but the trailer exceeds the min weight

required for brakes, so I put it on the car roof rack. Saw horses are to

allow the cradles to be wheeled off the trailer. A problem caused by the

second hand trailer.

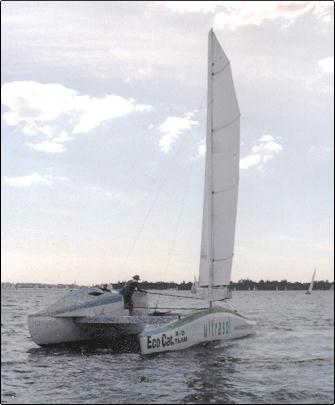

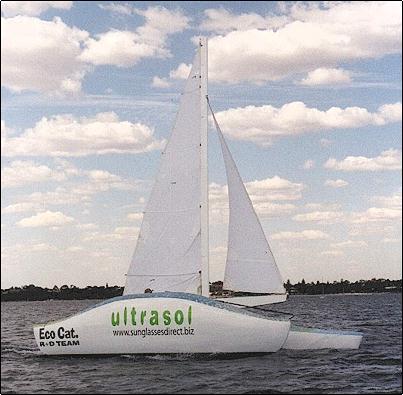

Sailing. Front rudder locked, steering with aft one.

Shunting, or maybe reaching....

View from windward. Will look better with windows.

Observe bend in the mast.

These photos were taken in 5-10 knots of breeze, boat

speed about 7 knots. Just before and just after we were well into double

figures, although it would be hard to tell from photos.

Been out on the river (4 mile fetch so the waves get

reasonable) half a dozen times in breezes from 0-25 knots. Harrigami

handles like a dream. Top speed so far is 14.8 knots, recorded on a broad

reach with 3 people on board and full sail in 15 knots of wind, measured

by the Bureau of Meteorology. So effortless that no one bothered to look

at the gps, which fortunately has a "top speed of the day" function. In 25

knots we did easy 9-10 knots tight reaching, with only a reefed main.

Plenty of scope for improvements in all wind strengths. The rudders work

well, shunting is very easy, even without the jib, and/or in confined

spaces. The sailmaker cut down the jib a little more than necessary, so

the mainsheet loads are high. Needs 2 hands to sheet on with the 1:1

sheet, or a judicious luff. Without the jib, (used as the first reef) a

detachable 4:1 tackle handles the loads pretty easily.

Tried angling both rudders to windward, and the boat

achieved negative leeway, but at a high cost in speed lost. Should be

enough to prevent anyone passing close to windward, or starting to

windward of us.

Changes so far include better hinges and locking system

for the beams, although I think that single piece, demountable beams may

be a better idea. The trampoline is a disaster as it keeps stretching,

particularly when wet. Discussions with the supplier are ongoing.

The mainsail halyard lock was excellent till it broke. I am still at the

drawing board on this. Everything else is pretty much as designed.

The paint job was done by Michael, from EcoCat R&D. It

is instead of fairing and saved a lot of work and bog. We will be letting

him loose on the sails when the recuts are finished. The "Ecocat R&D team"

is a group of guys keen on building lighter, cheaper boats and components.

They will build a Harrigami to sailing stage for $Aus20,000/$US10,000,

plus materials. Freight to most major ports is about $aus4,000.

Only problem at the moment is the mast, which is far

too bendy. This makes decent sail shapes difficult, and in a seaway, the

shrouds going from slack to tight really shakes the boat around. Apart

from this, the motion of the hulls through the waves is very smooth.

The mast problem is not easily fixable, so I have

decided to build a new one, testing a technique which will enable amateurs

to build them at a reasonable cost. More on this once it has been proven,

but it should lower the materials (including plans) cost for a ready to

sail Harrigami from $Aus20,000/$US10,000 to $Aus15,000/$US7,500, not bad

for a 10.5m/35 footer with full accommodation. The Easyrig is still my

choice for cruising, but I suspect that for racing, the lack of ability to

sheet the main down the traveller without moving the jib track to windward

is costing us some pointing ability. Consequently the new rig will

initially be a windsurfer type. This will require a sheet winch, but will

save considerable weight in the boom. The mast will not require shrouds

and will be telescoping. This allows access under Perth's bridges, makes

raising it on the trailer much easier, reduces windage on the mooring and

when reefed, and will turbo charge the already impressive light air

performance.

Current plan is to build a minimal windward hull

(partly for reduced sailing windage, mostly for easier trailling, it is a

4,000 mile trip) and maybe longer beams and take it, with the new rig,

across to Sydney for AMOC (Aus Multis offshore champs) in October. A crew

position is for sale to the highest bidder, if anyone is interested.

Trailling is not yet perfected, due to the drawbacks of

a second hand trailer. It will be much easier with a custom trailer and

some practise. Took me 6 hours from arriving at the ramp to launch. Pretty

lousy, but there were mitigating circumstances. It was 35 degrees C, I was

solo and a lot of the fixings are still temporary. I also got into a bit

of a mess raising the mast. With improved systems and an assistant, a 2

hour time will be possible.

Sue and I slept on it last weekend. No problems. This

is not cruising, but there are no indications that it will be any less

enjoyable than Harry was.

Havent got a motor yet, which accelerates the sailing

learning curve! In no wind, I can paddle (single oar, sitting on the beam)

it at 2 knots (gps) and about half this into about 10 knots of breeze. In

25 knots (today), I haven't a chance, had to drop the anchor and swim a

rope ashore.

As you can see from the pics, Harrigami has 2 sponsors.

Anyone looking at the Ultrasol website (when they finally get it running),

please mention Harrigami, and ideally, buy a pair of sunglasses. They are

putting on a big launching party next week. It is at a marina 25 miles up

the coast so Harrigami will get a decent workout coming back into the

20-25 knots seabreeze.

After a lot of indecision about whether to sell plans

or not, I have found an expert draftsman, Mark Stevens, who will be

drawing the plans. Like me, Mark is in the proa game primarily because he

enjoys fast, light, low cost boats.

Mark's wife Michele is a web whizz and is handling the

web site. Address to be advised when it is up and running later this

month. Once this happens, progress reports will be posted directly to the

web.

About Harrigami:

Harrigami is a folding, traillerable proa based on what

I learnt with Harry (Harry + folding/origami = Harrigami), my 12m/40'

proa. Harrigami is 10.5m/35' long, 5.25/17'6" wide and has all the

accommodation in the windward hull, the short, fat, high one in the

photos. This hull has full headroom, a huge double bunk and a single, plus

table and seats, the galley and toilet, all of which were to be installed

before it was launched. It is 8m long (Harry's was 7), wider and better

set out. The materials weight of Harrigami ready to sail was 525/kgs 1150

lbs. The finished weight is 550 kgs, with bunk and galley installed, but

table and seats yet to be finished, or started, for that matter! For

racing, the windward hull is easily detached and a much smaller, lower

drag hull installed. The long skinny hull is always to leeward and has the

rig and rudders in it. Harrigami will use the rudders and rig from harry.

Perth is far windier than Brisbane, and the boat is lighter so the rig has

been reduced in height and area.

Harrigami took 449 hours to this stage, including

mistakes, testing, thinking time and cutting and shutting to lower the

cockpit floor, excluding a few weeks of messing about with the trailer,

the paint job (68 hours), altering the boom, mast and rudders from harry

and playing with the folding system. Materials for the hulls and beams,

including consumables and the trailer came to $5,435. This includes some

bargains, which may or may not be repeatable. In the unlikely event that I

learnt the lessons from this one and applied them to building another one,

I would expect to have a much better job in under 300 hours.

I have an Excel spreadsheet with a fairly complete

breakdown of the costs, weights and time. Anyone wanting this, please ask.

If you can't use excel, let me know and I will send it as text.

For more information and some pictures of harry and U

(7m prototype of harry) have a look at

https://www.schachtdesign.com/proafile/volume_1/U.html

https://www.duckworksmagazine.com/designs/harry/

https://groups.yahoo.com/group/proa_file/files/Rob%20Denney/

Any questions, please ask.

Regards,

Rob Denny

carbondesign@dingoblue.net.au

|