|

|

Building

and Sailing a Bolger Windsprint

By Jack F McKie

|

|

Background

Back in the late 1980s I wanted a sailboat to get back on the

water that is so abundant here in Western New York State. I wanted

a sailboat that was easily single handled but would also carry

a passenger. I couldn’t afford to buy a new wood boat and

didn’t want a used fiberglass boat. I decided that the best

option was to build a boat since I am fairly adept at woodworking.

Having read Payson’s “Instant

Boats” and “New

Instant Boats” I decided to build Windsprint

primarily because of the double ended design and simple no lofting

construction. At the time I was leery of the offset daggerboard

and lug sail but decided that I liked the look of lug sail and

decided that in principle the offset daggerboard would work. I

sent to H.H. Payson for plans and to Bohndel for a sail. I bought

the sail first in order to have everything I needed in advance

as well as to pressure myself into completion of the project.

The plans arrived with the sail following shortly.

Building

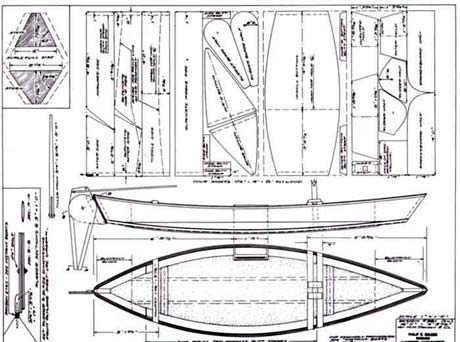

Once the plans arrived it was easier to see the plan detail. One

concern I had was that I felt there was a need for floatation

in case of capsize. I drew in the flotation tanks fore and aft

on the plans and decided to add them. As it happened, they were

to be a welcome addition in the future.

Having been around boats in the

past I “knew” that I needed top quality wood. I managed

to find some clear douglas fir two by fours that would be used

for the chines and rails as well as some fir marine ply. For glue

I decided on West™ epoxy. The few fittings required were

either purchased or made. The only fastenings used were a few

brass screws and bronze ring shank boat nails.

To begin construction I cut all

the plywood parts per the drawings. This went relatively quickly

using a circular saw and table saw. Next, I ripped the chines

and rail laminations from the douglas fir two by fours on the

table saw which was a fairly lengthy and dirty process. Once all

the parts were cut out (except the flotation tank parts) I was

ready to start assembly.

First in the assembly process

was to make up the sides with their butt joints. I considered

scarfing the sides but decided to stick with Bolger’s design.

Once the sides were made up and the stems ripped out of fir the

assembly was ready to begin in earnest. Assembly goes pretty much

as described in Dynamite Payson’s description of building

Teal in “Instant Boats” but on a slightly larger scale

with more joints. One exception to this is the laminated rails

which are fussy to laminate but not difficult. I used epoxy throughout

building this boat including coating the ply with resin. Once

the basic hull was built and set bottom down on the garage floor

it was time to build the flotation tanks. I penciled in the location

of the tank tops and bulkheads deciding to place the tank tops

below the shear line in order to allow grabbing onto the rail

all around the boat. The aft bulkhead was located at the aft edge

of the butt joint while the forward bulkhead had to be located

just forward of the mast step and mast partners. One by two fir

was used to frame in the tanks with bevels being determined with

the use of a batten and bevel gauge. Patterns were made from the

framing and the bulkheads and tops were epoxied in place. The

following two pictures show the hull at this point having just

been washed prior to further construction and fitting out.

The first picture is looking forward.

The holes on the bulkhead are for Beckson™

screw type deck plates to allow access and storage. Storage in

the flotation tanks is limited due to the small six inch opening

but it is useful for odd lines, paddle, anchor, etc. Note the

level of the flotation tank top that allows one to grab the gun’l

at any point on the boat. At this point the hull was ready for

the aft thwart and mast partner as well as the daggerboard, rudder

and rig.

I built the mast partner as a laminated

piece to allow for a more simple design than shown in Bolger’s

drawing. The rudder and daggerboard were laminated from one quarter

inch ply per Bolger’s design though I made the daggerboard

one quarter inch thicker. Building the spars was not difficult

but finding the material wasn’t easy. I used clear spruce

two by fours ripped for the boom and gaff. I made the gaff and

boom an inch or two longer than the plans specify to assure the

sail could be set properly. The mast was hollow and built of Sitka

spruce as shown in the drawing. The biggest difficulty in making

the mast was clamping and making sure that the mast was straight

and true. I considered a solid mast but I had difficulty finding

suitable two by fours and felt the weight savings was worth the

effort to make the mast hollow. The box section mast Bolger designed

for Windsprint is probably the easiest hollow mast you

can build and is extremely strong. I glued many small triangular

blocks in place on the wide staves in order to locate the narrow

staves for glue-up.

Fittings on the hull are two bow

eyes, one being fitted to the top inside of the stem and the other

being at the bottom outside of the stem. The rudder was hung on

home made brass hardware machined from brass bar stock I mounted

two cleats on the sides of the mast for the halyard and one for

the downhaul. The sheet requires only one block mounted on the

rudder. I used chrome plated aluminum half oval strip for the

rub rails.

Once the boat was ready to

rig I did a dry run in the back yard since I wasn’t familiar

with the Lug sail and wanted to get the bugs out at home where

tools and materials were handy. Rigging Windsprint went smoothly

with out a hitch. The sail from Bohndel was superbly cut and shaped.

If I had to complain about the rig it would be about the time

it takes to bend sail on using the lacing and again taking the

lacing out when finished. Using sail track or a bolt rope to attach

the sail might be an option. A better option might be keeping

the sail on the spars and using a canvas cover.

Sailing

After a trailer was purchased I

was ready to sail the boat for the first time. I took the boat

to the local boat launch and rigged her in about a half hour.

Once launched it was time to take a first sail and see if my time

and money were well spent.

Being used to small one design

sailboats and a small gunter rigged catboat this was a new experience

sailing a Lug rigged boat. Although the rig looked much different

than anything I had sailed previously, I found nothing to complain

about. She spun on a dime, followed through stays smoothly, and

sailed about without much fuss. The relatively large rudder and

daggerboard surfaces make for positive directional control. Windsprint

is sensitive to crew position and weight placement. After sailing

for a few minutes I found that placing my weight so it was as

close as possible to the aft edge of the daggerboard made a big

difference in performance. Windsprint is a fairly tender boat

for her size and flat bottom but anyone who has sailed small boats

before should be comfortable.

Once I sailed Windsprint in about

a thirty mile an hour + wind. A fellow had been watching me sail

earlier that week wanted a boat ride. I took him for a sail against

my better judgment. The experience was interesting. This fellow

was pretty heavy duty and I am not exactly small. I think our

combined weight was about 400 lbs. We went out of a sheltered

cove on a beam reach across Long Lake in the Adirondacks. When

the full force of the wind hit as we came out of the cove the

boat heeled only slightly and began to really fly. The rig was

pulling hard on the sheet and there was visible flex in the mast.

The boat was on a plane a few brief moments and we flew across

the lake. Water boiled in her wake. The centerboard and rudder

sang as they vibrated through the water. We came about and flew

back to the cove. My main concern during this adventure was breakage

with bringing the boat about at the end of the reach with out

capsizing being a close second. Windsprint did this under strain

but with out mishap.

Looking at the plans initially

I was concerned with the offset daggerboard which from the standpoint

of balance and lateral resistance seemed just as efficient as

it would be in the center. I was also concerned about the ability

of the lug rig to go to windward. I think that the rig goes to

windward about the same as a gaff cat and in practical terms does

quite nicely.

One unexpected negative aspect

of the Lug rig was running in a strong wind. Under this condition

the boat would roll side to side in an uneasy manner. I found

that this was eliminated by sheeting in the sail more than normal

for running keeping the gaff perpendicular to the centerline of

the boat. Another drawback to the rig is that in any wind it can

be difficult to set sail in open water due to the gaff and loose

sail flailing around. Windsprint is best launched with the sail

set from a beach, shallow water, or dock.

Reefing the sail was ok on the

first reef but the second reef destroyed her windward ability

almost entirely. I don’t know if this was the fault of the

type, sail or skipper but I found the second reef useless. One

nice thing about the lug sail is that if the spars have a little

flex you can flatten the sail a little by tightening halyard/downhaul

which makes for better performance in strong winds.

Only once did I capsize.

I am embarrassed to say that I fell asleep at the helm on a very

calm day and the boat jibed and….. Needless to say it was

a rude awakening! I was thankful for the flotation. First thing

I did was get a life vest on and try to right the boat. I got

the vest on ok but righting the boat alone was another thing.

I ended up pulling the rig, righting and bailing the boat, and

re rigging. The toughest part of getting the boat back under sail

was re-stepping the mast. If the mast had been solid I would not

have been able to do it because it was tough enough with my light

hollow mast.

Hindsight

My Windsprint was built very close to Bolger’s

plans with the only major deviation being the flotation tanks.

As designed, Windsprint is a nice boat indeed and sails well.

That being said, Windsprint has some weak points that

I would address if I were to build another. Using 20/20 hindsight

I would make the following changes.

The first change I would make is

to use cheaper materials in general utilizing wood that isn’t

perfect. I wasn’t all that impressed with the quality of

the marine ply I used and think spruce from the lumber yard would

have been adequate instead of the expensive clear fir. I would

still use the epoxy for glue but might skip coating everything.

I would use ordinary house paint rather than marine paint. I would

make all the fittings and consider use of figure eight lashing

instead of rudder hardware.

The one quarter inch ply bottom as designed is way too flexible.

If I were to do it again I would opt for a scarf jointed three

eights inch bottom with grain oriented across the bottom in order

to strengthen the bottom. In addition I would add a one by eight

cross section center keel set flat on the center of the bottom

and eliminate the “skids” shown in the plan.

Although the big open cockpit may

sound desirable, I found it a problem. In rough water and some

wind there simply isn’t anything to grab onto or get a foot

hold on. Add some water in the bottom to this and you will slide

around the bottom. There is no where to sit in this boat, other

than the bottom, which can be fatiguing at times. I am familiar

with the typical one design centerboard in the middle with hiking

straps which make for a more comfortable and safe sail in some

wind. I would move the daggerboard case to the middle of the boat

and add a rowing thwart. This would also help stiffen up the bottom.

I asked Bolger about a centerboard but he vetoed that saying that

the daggerboard would perform much better. I still wonder about

the centerboard because I have seen it in a drawing of a Chesapeake

crab boat of similar in form to Windsprint that has a

centerboard. A centerboard would probably spoil Windsprint’s

agility and would certainly add to her weight.

The mast was fine but that was

before I knew about the bird’s mouth mast building technique.

I would opt for a bird’s mouth mast on about the same taper

shown for the hollow mast in the drawings. I would probably use

ordinary spruce or linden rather than the expensive Sitka.

The sheeting arrangement as in

the drawing can be hard on the hands. I would try to work out

a way to use a cam cleat for the sheet and maybe add some mechanical

advantage to the sheet.

The sail I bought was outstanding

but I would tell the sail maker to forget the second reef and

save the labor.

One thing I was originally against

was adding oars. Now I would add the rowing thwart and definitely

add oars to add to the versatility of Windsprint.

Conclusion

To my eye, Windsprint

is one of Bolger’s finest designs. With a few modifications

this boat is an outstanding day sailor for protected waters. Although

great as a trailer sailor this boat would really make an ideal

row/sail boat for a cottage on a small lake. This would be a great

boat to teach a youngster some basic woodworking skills and how

to sail. I also wouldn’t rule out doing some fishing on

a quiet lake with Windsprint.

Jack F. Mc Kie

Freshwater Models

97 Alpha St

Rochester, New York

14612-2175

585.581.1399

w00dboat@yahoo.com |