Piragua

by Joe

Wiseman

I don't recall exactly when

I started building Jim Michalak's Piragua,

but building time was approx 20 hours, not counting drying time.

I am pretty slow, and made several patterns during the process

in case I wanted to make another boat.

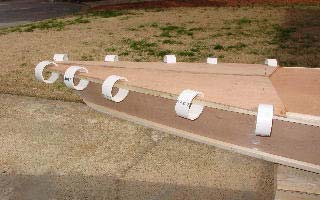

Sides and chine rails in place

Bottom glued and trimmed with router

I used the typical Luan 1/4

inch ply, and the highly touted PL Premium glue for most of the

construction. I did make my scarfs and floor joints from West

epoxy since it is a known quantity, and the PL is new to me. I

was impressed with the PL's holding power and price, but did not

like the bubbling that occurs during curing. If you like smoothly

fared joints, it generates much added work. If one is not that

particular, or it is used in hidden areas, it would seem a good

choice. I'm a bit fussy so I will probably stick to epoxy next

time.

Clamping outwales

Taping seams with epoxy

For chines and gunnels, I

scarfed 1X3X8 furring strips together then ripped them length

wise on the table saw. This gave me two 16 foot pieces for each

pair of furring strips. If you pick through the stacks, you can

usually find fairly clear straight stock, in my case, for $1.80

each, from Lowes home center.

Foredeck clamped in place

The only deviations from

the plans I made were to put a peak in the fore deck, both for

strength and eye appeal, and to use a inwale and outwale, rather

than two outwales as per plans. The latter was for purely cosmetic

reasons. I felt Jim knew best how to build his boat, so I otherwise

stuck to his specs.

Checking position for seat and foot

rest

Seat and mast step installed

Paint was exterior latex

over latex primer, also from Lowes. This was a first for me. What

a treat to work with latex rather than boat paint. We will see

over the long run if I am happy with it.

Ready to go

My after thoughts are: the

boat is a bit heavy (around 60-70 pounds I would guess) the result

of overly heavy chines and rails and 3/4 stock for back up plates

for joining the plywood. This seems to me as over kill. I used

a piece of 1/4 plywood on the inside and two strips of epoxy/cloth

on the outside of my floor seam, which I guess is another deviation

from the plans. I have total confidence in this type of joint.

Jim seems very conservative about such matters, and I can understand

that. His plans were excellent and the best value in the industry,

as many others have attested.

Marilyn trying out the Piragua

I have ordered plans for

Jim's "Twixt"

which I hope to build soon. Next, is a traditional Chesapeake

Bay fishing skiff from lines taken from an old time builder in

Reedville, Virginia on the Eastern Shore of Chesapeake Bay. Other

than using a plywood bottom rather than cross planking and a bit

of epoxy here and there, it will be made from the traditional

Juniper wood with traditional lines. I will keep you posted.

Joe Wiseman

VA. Beach,

Virginia |