Another Saturday, and another opportunity to spend several

hours on the Big Twin, after an early morning 2 hour paddle

in the Larsboat

on the near-by Meramec River.

(click images to enlarge)

(click images to enlarge) |

The first thing that I did was to remove the magneto that

I had previously re-mounted; not due to any problems, but

because I had decided to make the installation of a lanyard

equiped safety shut-down switch the subject of a future column,

and the Big Twin would serve as a guinea pig for that. So

the magneto was removed and some alterations made and a few

photos taken and then it was remounted.

One may have noted that in the previous part of this column,

I made no mention of setting the "gap" on the ignition

points before testing for a spark; this was not an omission

in my writing. I just forgot to adjust them. That the ignition

system would still produce a spark is a testament to it's

reliability. After reinstalling the magneto today, I did remember

to adjust the point gap to .020, using a cheap feeler gauge

and a regular screwdriver which are the only tools required.

One may have noted that in the previous part of this column,

I made no mention of setting the "gap" on the ignition

points before testing for a spark; this was not an omission

in my writing. I just forgot to adjust them. That the ignition

system would still produce a spark is a testament to it's

reliability. After reinstalling the magneto today, I did remember

to adjust the point gap to .020, using a cheap feeler gauge

and a regular screwdriver which are the only tools required.

The flywheel was then installed and torqued and the recoil

starter remounted.

I make it a habit to always replace the fuel hoses on any

engine that I am "refurbishing," and the Big Twin

was no exception. The only hoses on this - pressure-tank-utilizing

engine are the hose which conducts the pressure from the crankcase

to the "quick connect" fitting, and the hose from

the quick connect fitting to the carburetor which carries

the fuel. Although this engine had a fuel strainer incorporated

into the carburetor, I added a small "in-line: fuel filter

as well, which is my habit.

Finally,

the adjustment synchronizing the ignition advance to the carburetor

throttle valve was made. On most of these old OMC's this is

no more complicated than loosening a tapered "cam"

and moving it back and forth until the throttle valve begins

to open when the valve's "follower," which rides

on the cam, reaches a certain mark on the cam. No "diagnostic"

computer needed.

Finally,

the adjustment synchronizing the ignition advance to the carburetor

throttle valve was made. On most of these old OMC's this is

no more complicated than loosening a tapered "cam"

and moving it back and forth until the throttle valve begins

to open when the valve's "follower," which rides

on the cam, reaches a certain mark on the cam. No "diagnostic"

computer needed.

What WAS now needed was a solid mounting surface in order

to attempt to start the Big Twin, and the AF4

provided that; the Big Twin was clamped to the transom with

it's "leg" submerged in water in the plastic 55-gallon

drum that serves as my outboard motor :"test tank."

The low- and high-speed mixture adjusting needles were set

at about 1 full turn open (not the correct setting it turns

out) and I commenced to "yanking" on the starter

rope of this manual-start-only engine.

After

a few pulls, the thing actually started, coughing and wheezing

as it blew smoke and water in large quantities; some fiddling

with the mixture controls settled it down a bit, and I left

it running at a fast idle while I took a few photos. Then

the thing coughed on last time and quit. I cranked it over

several times, then several times more, and then some more,

but it would not start.

After

a few pulls, the thing actually started, coughing and wheezing

as it blew smoke and water in large quantities; some fiddling

with the mixture controls settled it down a bit, and I left

it running at a fast idle while I took a few photos. Then

the thing coughed on last time and quit. I cranked it over

several times, then several times more, and then some more,

but it would not start.

I made some adjustments to the mixture needles and pulled

the rope some more and it still would not start.

A few more adjustments, then some tries with the choke off,

then with the choke on, then with the mixture needles screwed-down

shut (in case it was flooded) but nothing would coax the engine

to fire-off.

It is at this point in the process that people tend to become

irrational and end-up yanking the starter rope until they

are blue in the face, or end up grinding away at the electric

start until the battery is dead, or until the starter motor

overheats so bad that it throws it's solder all over itself

and self-destructs.

After about 10 minutes of attempting to start an engine that

had been running just moments before, I decided it was time

for some trouble-shooting. since numerous adjustments had

already been made to the carb with nary a hint of an intention

to run again, I decided to check to see if the magneto was

still working. Removing the spark plugs and grounding them

to the engine block revealed no spark when the engine was

cranked. The recoil starter was removed and the flywheel slowly

rotated by hand, revealing a slight"clicking" or

snapping noise. Could be a spark jumping to a "ground,"

or could be something hitting the flywheel. Since I was careful

to check for any interference with the flywheel when I mounted

the magneto, I could not believe that there was a problem

now, but I drug out the flywheel puller anyway and removed

the flywheel.

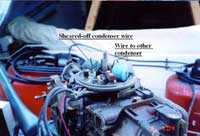

As

I lifted the flywheel off, I immediately noticed that one

of the condenser' wires was broken off; evidently the flywheel

magnet caught it and ripped it apart. That would prevent one

cylinder from sparking, and while a properly turned 2-cycle,

2-cylinder engine will often run on one live cylinder, the

Big Twin had only been running for a minute or two and was

far from being "in tune."

As

I lifted the flywheel off, I immediately noticed that one

of the condenser' wires was broken off; evidently the flywheel

magnet caught it and ripped it apart. That would prevent one

cylinder from sparking, and while a properly turned 2-cycle,

2-cylinder engine will often run on one live cylinder, the

Big Twin had only been running for a minute or two and was

far from being "in tune."

I replaced the damaged condenser with one from my stock, and

also rechecked the point gap setting (as one should always

do whenever the magneto is disturbed,) and "buttoned-up"

the engine again, making darn sure that the wires underneath

the flywheel were routed well clear of rotating parts.

A

few more pulls on the starter rope and the engine fired-up

again. A few minutes of running showed that the engine was

most likely ambitious-enough to keep running for a while.

It also was pumping cooling water well, although after several

minutes the discharge water began to heat-up to the point

that it was almost too hot to keep one's hand in the stream.

An outboard run in a bucket can overheat very easily, however,

so while it is an item to check carefully during the engine's

first run on a boat, at this point I will not consider it

a problem.

A

few more pulls on the starter rope and the engine fired-up

again. A few minutes of running showed that the engine was

most likely ambitious-enough to keep running for a while.

It also was pumping cooling water well, although after several

minutes the discharge water began to heat-up to the point

that it was almost too hot to keep one's hand in the stream.

An outboard run in a bucket can overheat very easily, however,

so while it is an item to check carefully during the engine's

first run on a boat, at this point I will not consider it

a problem.

Tomorrow I will haul the AF4

and Big Twin down to the launch ramp on the Meramec River,

where the park gates are unlocked at 7:00 am but the gentleman

who collects the ramp fee does not arrive at work until 8:00,

leaving me with a one-hour "window of opportunity"

for a free launch.

On to Part

4