Rope Wrapping for Oars 101

|

|

| by Pat Patteson - Molalla,

Oregon - USA |

I have several sets of oars I use with different

boats I have built.

Boats from a Bolger, “Elegant Punt”, through

a Bolger “Gloucester Gull” up to a “Rapid

Robert”, 14’, square stern drift boat

and several others.

All my boats are pretty basic, plywood, “Work

Boats” and I don’t think a nice, leather

oar wrap is appropriate for any of them.

But, I do need to protect the looms that see some

very heavy use, especially on the Drift Boat. I used

the term “Sets” of oars rather than “Pairs”

because I always carry 3 oars in my drift boat.

It only takes a second to lose or even break even

the strongest oar and there’s No chance to go

back a get a lost drift boat oar, especially with

only one oar left.

Instead of using leather wraps, I decided to wrap

my oars with “Rope”, the traditional Northwest

Driftboat method. The rope wraps give long-term protection

and if properly sized really hold the oars in the

oarlocks.

There are a lot of times, when drifting, that I

need to drop my oars to help my wife, Kay land a fish.

Kay is the fisherperson. My job is to get her to where

the fish are. With properly sized locks and properly

sized rope wraps there is little danger the oars will

slip out of the locks and the oars can drag in the

water. While not quite as nice Looking as real Leathers,

the rope wrappings do Look pretty good and are not

difficult to make.

Here’s a brief description of how I make rope

wraps for My oars.

I used heavier than usual rope here to illustrate

the process.

The first, very important step is to find a cord/rope

that is the right diameter, that when wrapped around

your oar will fit in the oar lock but not slip out

between the horns. I've used 1/8" up to 1/4"

line for different size oars and locks. The thinner

the line, the more wraps you will need to make and

the nicer the wrapping will look, but sometimes thicker

line will be needed to prevent the oar from slipping

out. The rope I have found best is round, nylon, “Braided”

line. Looks like old fashion, cotton clothesline cord

and comes in several diameters.

The wrapping I do is similar to what I have done

to wrap eyes on home made fishing rods or to tie fletches

(feathers) on home made arrows. Back when arrows were

wooden dowels and fletches where real, split feathers.

The start is pretty easy.

Determine where the lock will come on the oar and

start the wrap a few inches above that. Tuck one end

of the wrapping rope along the oar and start wrapping

back over the end so there is no loose end hanging

out.

Tuck one end and start wrapping

The other end is trickier.

Continue wrapping until you get to where you want

the wrap to stop.

Then cut the line a few inches longer. (the length

of the distance 5 or 6 wraps make on the oar. Hold

or tape the wrap about 5 or 6 wraps from where you

want it to stop and then loosen the wraps beyond that

but keep it all from unwinding.

You will also need a foot or more of thin, lightweight,

but strong

“string” or very light line.

Make a loop with the light line and slip it between

the wrappings that 5 or 6 wraps back so the loop goes

under all the last few wraps. Then insert the end

of the wrapping rope through the loop so you can use

the loop to pull the end back under the last few wraps

so the end is hidden under the wrapping, just like

the start.

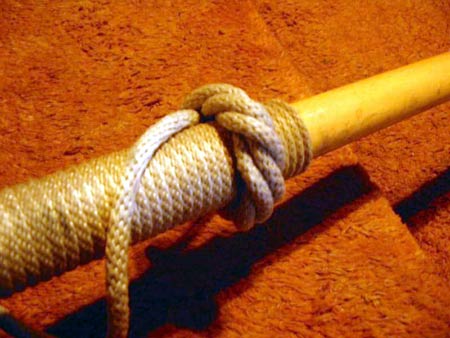

Ready to pull the end through...

...pulling the end...

...the end in place

With the taped wraps still tight, start twisting

the loosened wraps to get them as tight as you can.

Takes a while to do that last twisting, tightening

thing, but when you get done the wraps should be tight

all the way to the end with the end of the wrapping

pulled tight and hidden under the last few wraps.

Here’s a picture of the rope wrapping on one

of my light oars. In the photo below, I attached a

commercial rubber Button that is force fitted over

the wraps but a nice woven loop like the one above

could be used as well. I slather thin epoxy over the

ends of the wraps to keep them from unraveling. Might

have to repeat that every so often as UV will eat

the epoxy after a while. Varnish or some other clear

goop might work too.

Here’s the finish product.

The trick that's hard to tell in words, but easier

to show, is the Loop

of light line, under the loosened wraps that allows

you to pull the end

back under.

But, if you play with this Idea, it might become

obvious ? ?

Good Luck

And,

Happy Rowing

Have Fun

Pat Patteson

Molalla, Oregon

Other articles by Pat Patteson:

|