NOTE: EasyB plans have been updated as of Jan 2011 - click HERE to download the latest version.

Introduction

Every time I paddle away from shore

in EasyB after spending time in other boats,

mine or others, I’m amazed again at how easy

she moves up to cruising speed. Chuck had expressed

an interest in publishing the plans as a freebie but

I declined since the essence of a computer designed

boat is in the full size frame patterns and I wasn’t

ready to supply paper for nothing. Fast forward a

few years and Adobe’s pdf format has improved

printing capabilities and my ability to present designs

in pdf format has improved also.

So here is the current iteration of EasyB

including full size patterns requiring a smidgen of

cut and paste if you can print tabloid size, a bit

more at letter size. The only change from the prototype

was to respace the stations to 8” and redo the

stem profile (again, several times, it is a hard curve

to get right).

Plans are presented as is, there are a lot of good

resources regarding stripper canoe construction and

it seems most people will follow their personal preferences

in any case. Anyone building EasyB for sale

might keep in mind there is a large dose of good karma

in compensating the designer for his efforts and some

risk at the other end of the spectrum.

As always I’d be interested in discussing custom

designs/commissions for those interested in such.

EasyB Design Brief

After several years there’s nothing I’d

change in the overall shape of the boat, except the

stem profile. The following is taken from the original

brief with comments on construction changed in tense.

The boat’s shape is derived mathematically

with parabolic curves for plan and profile with superelliptical

cross sections, which guarantees a perfectly fair

shape capable of being manipulated over a wide range.

So our boat is 11’-8” L.O.A. 28”

maximum beam, a bit asymmetric, the midsection 8”

back from the midpoint. The sheer forward is fairly

pronounced both for appearance and to make stripping

easier at the chin of the bow. Just a little rocker,

don’t need a lot of maneuverability in such

a short boat and less rocker also keeps the prismatic

coefficient up a bit, also a good thing in a short

boat. Since an absolutely straight keel line offends

my sensibilities somehow an inch or so will do. At

the 4” waterline, our little boat will displace

4 plus cubic feet of fresh water or 255 pounds with

a prismatic coefficient of 0.56 dragging 18.5 plus

square feet of wetted surface through the water. It

will take about 82 pounds to sink the boat an inch

lower in the water, which should be about as much

as you’d ever want to load the boat. Take 80

pounds out of the 255 leaves 175 pounds and you’ll

be able to float in 3” of water.

Take all this stuff with a small grain of salt, freshwater

or not. In the real world of wind, waves, current

and all sorts of macrocosmic chaos I don’t begin

to understand, A boat is a living dynamic thing, constantly

changing and adapting to the conditions of the moment.

We should all do so well.

Construction is conventional wood stripper, ¼”

nominal wood strips with a layer of glass/epoxy both

sides, 5-oz in this case. Actually 3/16” thick

strips would work fine for a boat this size, but I’ve

got a lot of ¼” thick strips already

on hand and have neither the equipment nor inclination

to take 1/32” off each side. Going to 3/16”

thick strips would save some weight though. There

is (are?) about 33 square feet of hull surface in

EasyB which corresponds to 0.6875 cubic feet of ¼”

strips or 0.516 cubic feet of 3/16” strips.

At 22 pounds per cubic foot that’s 15# versus

11.4#. Rather than trying to save 3 ½ pounds

on this boat, I’ll wait and build a really light

boat (15#) on same form using 9mm PVC foam, kevlar

and s-glass. So 15# hull wood, 5# epoxy/glass and

say 5# bulkheads, deck and gunnels and I’m carrying

a 25# boat (Actual boat weighed 26#).. This I can

do.

Back to construction. Though conventional scantlings

and lay-up, Easy B was built without using staples,

using rubber bands instead to hold the strips against

forms cut from ¼” pegboard. There was

reason in having 9” (now 8”) station spacing,

easy to do since the shapes are derived mathematically.

Bulkheads were laid up from scrap strips with glass/epoxy

both sides. Decks will be foam sandwich similar to

the Bionic Log, which will allow me to indulge my

minor obsession with book matching. Back when I was

ripping my own strips, It was simple to rubber band

strips together in pairs making it easy to book match

everything. Now I’m content to just book match

the decks with strips resawn to 1/16” veneers

laid over a foam base. Gunnels are spaced with spacers

cut from 1” popular dowels to contrast with

the mahogany gunnels. The extra width using this format

will allow us to not require any thwarts in the boat

plus have a multitude of places to tie or fasten stuff

and anchor footrest, leeboards or whatever.

EasyB has been a pleasure to use and I hope others

find some of the same joy.

The Plans

NOTE: EasyB plans have been updated as of Jan 2011 - click HERE to download the latest version.

Below are the various PDF files you will need to

build EasyB.

|

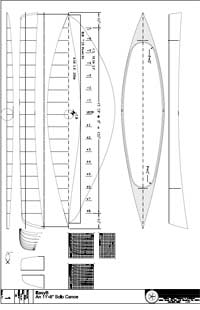

Here is the

overview. Click the image to download the PDF

file. |

|

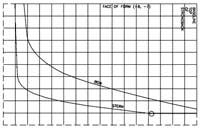

Here are the

bow and stern profiles |

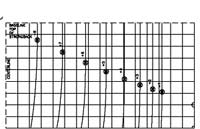

Here

are the station molds |

Fore Upper |

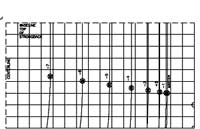

Aft Upper

|

Fore Lower |

Aft Lower

|

Other articles by Skip Johnson:

|