| Designing NACA

0000 Foil Sections

I do not claim to be any sort of expert

on the subject of foil design. I have only read up

on the subject and experimented with various tools

that I now own or have downloaded off the internet.

With that said, I only claim to be an interested observer

and tinkerer who likes to figure out how things work;

and spread any information that I have gained to other

tinkerers of like mind. Ducks of a feather so to speak.

When I was close to finishing the construction of

my first 8ft Nuthatch

Pram, I started thinking about what type

of rudder and daggerboard I would need and how big

each would have to be. That started a series of long

searches on the internet for informational theory,

and articles on foil design and construction. I found

some good sites here and there, and gleaned as much

as I could about the concept of foil design. I even

read several books on sails, hulls, and foil design

by C.J. Marchaj. The books are intended for more than

the casual observer; and/or those looking for an aid

in getting to sleep. It wasn't until after I had copied

down a very complicated mathematical formula for foil

design, to put in a series of cells in a spreadsheet;

that I came across the NACA4gen

program online in a zip file.

A quick download and install brought up a very basic

program in DOS. Luckily, I'm old enough to have cut

my computer teeth (still have most of them) in the

dark days of DOS. Always wanted a Mac in those days,

but couldn't afford one. Do you remember the blank

screen and the blinking prompt? Or all the sticky

notes with obscure symbols and letters stuck to the

monitor to remember how to make DOS work on your $5000

IBM XT?

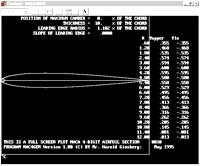

The 4Gen program just asks a couple of basic questions

with "mouse less" keyboard strokes. What's

the NACA number? Enter your XXXX number and then the

"cord" length (fore and aft width of foil,

not thickness). The program then spits out a diagram

of the foil and a text box to the right with the X

distances on the cord starting at the leading edge;

and the Y (+/–) offsets from the cord. There's

not much to the program, but the information is very

helpful. You will be generating several program inputs/outputs

until you find the "thickness" you need

for your foil. We will come back to this again later

in the story.

A little regression here, as older people always

seem to do. Stories always need a bit of filler to

make a point. Think of it like fiber in your diet.

Before I ever started looking for foil information,

I had played around with several blanks of 5/4ths

cedar. I knew what a foil should look like from sailing

other boats, and also from spending large sums of

money for the "go fast" fins I used on my

sailboards. "Try this one out, everybody

at the Gorge is using it!" I have some very

nice fins in the loft of my barn that the spiders

hide under now. So I would lay out some lines on the

blanks and rasp away, saw away, plane away, and throw

away. I eventually got one that looked ok, but the

thickness was a little off from side to side. I did

some more rasping to even it out; but what looked

like a foil close to an NACA 0010 when I started,

became an 0006. I had other things to do so I set

it aside. When I came back to it again, the foil had

warped to port. I read an article online about cutting

the cedar blanks into 1x1's and gluing them back together

after you change each one's location in the pile and

swap ends on alternating sticks. The alternating method

should reduce any chance of warping that may occur

later. I have one untouched blank glued up, but I

got strip foiled, Hallelujah, before I needed to use

it.

I got inspired one day cleaning up some 1/8"

scrap from making one of the boat models

you see in

other stories, hanging on the

wall in the background of my shop. I stacked several

of the pieces on top of one another and the light

came on. Now I only needed to find a way to figure

out how to do it. The 4Gen program gave me the numbers,

but I needed to add the necessary layers of 1/8"

plywood to the foil's cross section. Looking at the

foil outline in the 4Gen program gave me an idea.

I wondered if the program I used to design the hulls

of my boats could also generate the bezier curves

of the foil? No scab goes un-scratched here.

I copied down the numbers off the monitor screen

(use the screen capture

program linked at the end of this story and print

it out) onto a scrap of paper, and used

them to set up the "guides" (adjustable

grid) on the drawing page of my program. The main

information for us that 4Gen spits out, is the "thickness"

of the foil and how far back from the leading edge

that point is. On the bottom of page two of the accompanying

PDF file

for a NACA 0010 – 12 inch foil; the maximum

Y(+/–) measurement is 0.600 inches, and the

X distance is 3.60 inches from the leading edge. That

gives us a foil that is 1.20 inches thick and a cord

of 12 inches. The thickness will give us problems

as that is only 9.6 strips of ply, but is close enough

for this story. As I alluded to earlier, you will

be generating several 4Gen lists as you figure out

the foil that you want to make. You will want to see

what the 4Gen program generated, and what was the

overall thickness for each iteration; and how close

that doubled Y number was to a full thickness stack.

An odd number is ok, as the very center can be a single

sheet with even numbers of layers on either side;

as in the PDF example.

Note: I found the screen capture

program Captura

1.0 on the internet and have been very

happy with it's functionality. It's a very simple

program to use with the 4Gen program; and any other

uses you may have. After you have input your NACA

number and cord length, the program generates the

foil shape. Use the Control-C command to exit the

program, or type QUIT. Open the Captura program;

use the select area command and crop out the DOS

window with the 4Gen information. Save the file,

and remember to add the (dot)jpg file extension.

I have added a screen capture folder in my Irfanview

photo directory so I always know where they will

be. You can then either print out the file, or run

it minimized in the drawing program window as you

do your figuring.

|

|

Time for another side trip on computer programs.

The one I use everyday is no longer available, and

I can't find anything out there that comes close to

the ease of use and functionality that it has. I was

still using Win3.1 on a 386-25DX when I first got

it, and it still works on my P4 XP machine. Except

that Bill can't leave well enough alone, and now I

have trouble putting text in my drawings; and only

with M's and W's. Something to do with OpenType fonts,

the bastard child of TrueType. I was Beta testing

a 2.0 version of the program, but Win95 came out before

it was bug proofed; and they shelved it, even though

it worked fine on 95. Both Adobe Illustrator and PageMaker

would have been shelfware years ago if they had finished

ProDraw 2.0 on time.

You are in luck, in that the drawing program in OpenOffice.org

and the vector drawing program Inkscape

can do the tasks for laying out the foil cross sections.

Both are FREE, but neither touches ProDraw in power

or ease of use. Look for the links to both programs

at the end of this story.

Note: The rest of the story will assume

that you have one of the vector drawing programs

I have talked about or familiarity with the one

you already own.

With your drawing program running and on a blank

page, go to where you change the paper size and orientation.

You will be using 8 1/2 x 14 inch paper in the landscape

format. Also find and set the rulers to inches.

We will start by bringing in the first two "guides".

Usually dragged on to the drawing area from the top

and left hand borders. One will be a vertical, and

one will be a horizontal guide. Place the vertical

guide close to the left hand side of the page so you

have enough room to draw a 12 inch foil.

Find the "reset 0/0" button on the drawing

page and move it to the point where the guides cross.

The button is usually in the upper left corner of

the drawing boundary. Drag it to the intersection

of the guides. Look in the menus for the "snap

to guides" entry and select it. Look for the

"Zoom" function of the program and zoom

in on your new 0/0 point to see that it is actually

on the mark. Or find the "edit guides" dialog

box and make the adjustments there. Both should be

0/0.

In drawing #1 of the PDF

file that comes with the story, I have

added vertical guides at the maxim thickness point

(3.60) and at 6.0, 9.0, and 12.0 inches; and a horizontal

guide set at (0.600). Once you do this a few times

and prove to yourself that this method works; you

will only need the leading edge, maximum thickness,

and trailing edge vertical guides lined up on the

horizontal centerline guide.

Now comes the "fun" part. Don't you hate

it when people say that, cause you know it ain't true.

You need to find the "Bezier Curve" tool

to draw the "three point" line in drawing

#2, to form one half of the foil's outline. Good time

to look in "Help", as if it ever does. In

OpenDraw in OpenOffice.org,

it's in the tool bar on the left side of the drawing

page. Grouped with several other tools that slide

out to the right. Hold the mouse curser over the lower

left button in the group and it should say "curve"

or something like that. Click it and move the "cross"

back to the drawing and click the (0,0) spot on the

guides. Keep the left button down as you drag to where

the (0.600, 3.60) guides cross. Click there and go

on to the end point where the guides cross at (0,

12.0). Double click to end the line. You are done

with the curve drawing tool, and can go back to the

"pointer", aka the "selection tool".

Who's on first, what's up next?

OpenOffice.org can be a bear when dealing with the

handle points. Inkscape is easier, but as you have

found out, setting the 0/0 point doesn't exist. So

you have to add 1 to all the measurements on the X-axis.

0 is 1, 3.60 is 4.60, 12 is now 13. If you have another

program, or know how to use any of them; just make

sure the end points at 0/0 and 0/12 don't have any

"handles" sticking out that are attached

to the end "points". You want them

to be just "corner" points without any handles.

You will know something is wrong by the funky way

the line curves into the end points.

Double click the .600/3.60 handle point to select

it and then go looking for where the turn into "symmetrical"

point button is located. Make the .600/3.60 point

a symmetrical point and drag out the handle points.

You may have to put the mouse over the point, click

and drag out the handles. They may be looped in the

wrong direction, but you just need to twirl them around

to the correct orientation and drag them out. If the

end points are not corner points and have handles

attached; the curve you get will not look like the

one shown in drawing #3.

Drawing #3 on page 1 of the PDF

file, shows a horizontal guide centered

on the .600/3.60 point. Keep the point handle lined

up with the guide, and drag it out to the vertical

guide at 0/0 and release. That's it, you have just

created one half of the foil section. Now select your

new curve and go looking for the copy and flip commands.

Line up the leading edge point of the new flipped

curve (drag the line and not

the end point!) with the parent curve and go

looking for the "join" or "combine"

command. Make it so #1.

You can use a fill color to show that the joining

worked and can now save your file. You do save your

files right? You can move/set some guides to check

for yourself that the Y(+/-) values at the X distances;

do fall on (or too close to actually measure in the

real world) the arcs.

To figure out how many of the 1/8" layers you

will need; divide the total thickness (1.2) by the

thickness of one layer of ply (.1250). We get 9.6;

which works out to an odd number of ply's. So I "copy"

and "paste" a new cloned foil, and drag

it to an area below our first. Line up the leading

edge point on the vertical 0 guide. Drag

the foil and not the point. Drag down a new

horizontal guide to intersect with the leading edge

point. Drag down a a new 0/0 point at that new intersection

and to reset the 0/0 grid for a new task.

Add new horizontal guides above and below the 0/0

point. Go to the edit guides area and set these new

guides to +/- 0.0625. This will give you the thickness

of one sheet, split/centered over the new 0/0 horizontal

guide. Now take a pencil and paper and add 0.1250

to the 0.0625 numbers. This will give you the numerical

values (+/-) for the next pair of guides. Do this

four more times for a series of guide lines above

and below the 0/0 centerline of the foil.

Now fine the "rectangle" drawing tool

and drag one out starting at the location of the upper

corner of the "center" strip of plywood.

Drag this box out to the end and down at the - 0.0625/12

location. You have the first layer of plywood. If

it is still selected, click a color and fill it. You

will be using different "matched" colors

for each side of the foil. As I have done on page

2 of the PDF file.

You can see where one of the upper and lower horizontal

guides for the next layer of plywood crosses the foil

arc and where it also ends on the trailing edge. Place

vertical guides at those locations and drag out a

rectangle box using them as the end points for that

layer of plywood. Repeat the process with the remaining

layers. You now have the locations of the starting

and ending points of the "strip widths".

Click on the vertical guides to check the values given

in the editing dialog box. Adjust to a normal measurement

as needed, but still staying in the cross section

boundaries. On this cross section, the starting and

ending points fall close enough to standard measurements;

and we will use them as is, for constructing our NACA

0010 – 12 foil.

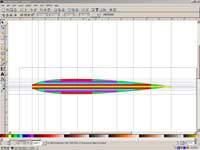

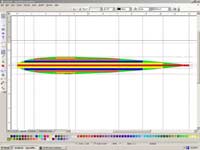

The following screen capture jpg's show completed

foil drawings done with the Inkscape (left) and Open

Office (right) programs.

|

|

The only thing left to discuss is what shaping needs

to be done at the tips of the foils. As I stated at

the beginning of this story; I'm not an expert on

any of the fine points of foil design. I can only

go by the information in the articles that I have

read, the shapes of the foils I have used with other

small boats; and in my collection of sailboard fins

and daggerboards. All of them have some shaping done

to the tips. Part of it is reducing wetted surfaces;

and part is increased performance. Water will prefer

to go around a "shaped" tip than across

a square one. This induces less turbulence off the

foil's tip and trailing edge. Less turbulence off

the daggerboard will help the rudder maintain it's

grip in the water when it gets there. I like to have

straight leading edges and taper off the trailing

edges of my daggerboard foils. This also gives me

a longer section of the thickest part of the foil's

cross section, for strength at the ends. This helps

when you are standing on the daggerboard during a

self rescue. The rudders, I leave a little boxy to

maintain working surface area.

I still haven't worked up any standard (researched)

numerical information about how big a foil should

be in relation to the size of the hull. I've been

leaning towards {db-cord in inches, is equal to hull

length in feet as inches, plus two inches}; so a 10ft

boat would have a 12 inch daggerboard cord (10"+2"=12").

The exposed length of the daggerboard is twice the

length of the cord. So a NACA 0010-12 would have 24"

exposed below the keel of the boat. The overall length

would be determined by the daggerboard trunk height,

plus room for the hand grip and depth stop. I try

to size the rudder to be 1/3 of the exposed surface

area of a fully lowered daggerboard. So far my sailing

boats have had no bad habits, and the estimated CLR's

(with fully extended daggerboard, no rudder) from

my scaled half model hulls, have been right on the

money to their full sized sisters. Push at that point

on the hull while it is sitting next to the dock,

and the boat moves away with no induced turning.

That's it, with the programs we have just used, you

can now design your own NACA 0000 foils. I hope all

this made some sense and I haven't confused you about

the process. If you don't want to download, purchase,

or learn a new computer program; everything can be

done with pencil and paper after you have generated

the numbers with the 4Gen program. You can layout

the X and Y values on graph pager, and outline the

foil's arc with a french curve and be close enough

to make a template. You can then figure out how many

plywood sheets are required and how wide each needs

to be from this method too.

The following are some links to sites for free programs

that I have used to help with this story. For ease

of use; the Inkscape vector program is less hair pulling,

but still in early development. I will be updating

the Inkscape program on my computer as it gains in

features and usability. It looks like a winner. OpenOffice.org

2.02 is a truly great, full featured "Office

Suite" program now, and can stomp "clippy"

into his much needed oblivion.

Links

Thanks again for reading my stories. I hope you enjoy

reading them as much as I do writing them. My next

story will be on how and why I design boats the way

I do. Until then, stitch and glue and stylish too.

Warren

Messer

Red Barn Boats

Other Articles by Warren Messer

|