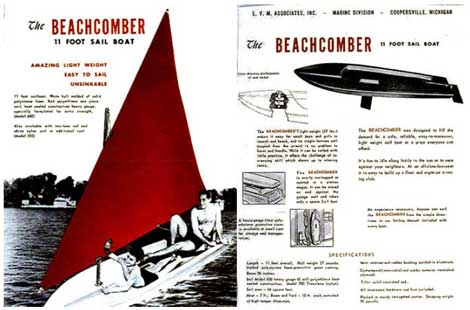

| I’m guessing

that the year is just after WWII either in the late

40’s or early 50’s when my boat was created

by L.V.M. Associates Inc. of Coopersville, Michigan.

The hull is of molded polystyrene foam, 11 feet overall

and weighs 27 pounds. It has a protective paint coating

and has a beam of 36 inches.

It came in two models

depending on the sail chosen. Model 600 was of red

“heavy guage (06mil) polyethylene heat sealed

construction. Model 700 was red and white striped

Translene (nylon). Both had a sail area of 60 sqft.

The mast was 7’

and the boom and yard were 10’ long extruded

high temper Aliminum (The mast step allowed for a

pole of just 1.125” inches in diameter,while

the rudder and centerboard were of varnished plywood.

Along the centerline

and 3” forward of the stern was a 6” aluminum

tube that had an inside diameter of 0.5” with

a steel washer crimped on top and bottom and served

as the rudder shaft tube. My quess is that originally

the Tiller had a steel threaded rod bolted to it,

to act as a pivot point and protruded far enough astern

so as to allow the rudder to be attached to it. Please

remember that this was before the word fiberglass

was invented or Kool Cigarettes were offering a “Snark”

for 2,000 coupons.

So much for the specifications

listed in the sales flyer.

Three years ago, my

then 12 year old grandson pulled the hull out of the

garbage of a distant neighbor on “Bulk Pickup

Day” and dragged it a ½ mile home where

it remained until this summer. All it had was the

centerboard, now painted blue and in the bow and stern

threaded steel rods corroded solid to their aluminum

sleeves.

About six weeks ago

I searched the internet to find something that looked

like this hull and found a brochure (two sides of

a single sheet) of what appears to be a duplicate

of this boat. Since that time I haven’t been

able to find that original site, but at least I have

the pictures and the specs to go by, in restoring

this hull to sailing condition.

Where to start? For

me it was the internet and while searching I surfed

into Duckworks and its links. I gained knowledge and

soon had in mind how my restoration would come about.

First, how do I restore

a 60 year old Styrofoam hull full of holes and gouges

especially around where I removed the steel shafts.

(Steel and aluminum don’t mix in a salt water

marine atmosphere.) My solution was to use a product

that my wife had purchased to eliminate drafts through

our exterior walls. It is called “Great Stuff”

and is a product of the Dow Chemical Co. It is a foam

sealant for cracks and gaps and ends up just like

Styrofoam. It was worth a try as it is also a bonding

agent to most materials. My only fear was that it

might dissolve the existing Styrofoam, it didn’t.

Soon the entire hull was pockmarked with expanded

bubbles of foam and one hour later with a fine tooth

hacksaw blade the boat was back to being at a uniform

surface level. What I discovered is that this too

is foam with thousands of tiny bubbles that end up

looking like the surface of the moon. Using an orbital

sander the boat’s surface was as good as I

could get it in the absence of a suitable substance

like “spackle” or “bondo”

substance might do for a sheetrock wall or a car’s

exterior body.

Next came two coats

of latex paint that did a good job if filling in some

of the small craters. Be aware that blue masking tape

is good only on smooth flat surfaces, I had to do

touchup all along where the blue met the white paint.

In the meantime the

search for aluminum poles started and while many Internet

sites including Ham antenna companies and fencing

companies also had them the cost of shipping anything

over 8’ by freight exceeded the cost of the

material. The answer was to find a local dealer to

avoid shipping costs, but that search was a dead end

also. On the way home from a fencing company, I stopped

at a pool supply company and found that for $23 apiece

I could buy a nested aluminum pole whose outer diameter

was perfect for my mast, and was 8’ long with

no alteration. The inner pole was 1” in diameter

and was also 8’ long so that the maximum length

was 16’. I only needed a boom that was 11’

and a yard that was 13’ but more important the

inner pole did not lock with a twist action, but rather

locked at the top of the outer pole with a compression

fitting. This meant that the inner tube could be locked

at any length and in any position you set it.

Being a lateen rigged

boat the boom and the yard are both not parallel to

the water but instead these two poles meet at a point

forward of the mast. I decided that the easiest way

to join these two poles was by means of stainless

steel eyebolts with an aluminum spacer tube with rounded

ends to exactly fit the inner diameter of the outer

tube so that the tube wall would not collapse when

the nylon stop nuts were tightened.

|

click

images to enalarge

|

You will note in the

above picture that while I could have interlocked

the two eyebolts but I preferred to join the two with

a shackle that would allow me to tie the Tack of the

sail to this junction.

Next I realized that

since I had an adjustable pole inside the outer pole

of the boom and yard, no fitting could be mounted

that went through these poles such as the hoist point

on the Yard, the gooseneck fitting at the junction

of the mast and boom, or the blocks used for guiding

the mainsheet along the boom.

I therefore designed

all these fittings so that they clamped around the

pole with junkbox parts. These clamps also have the

advantage of being able to slide the fittings fore

or aft to find the ideal location for each one.

This is my gooseneck

fitting using a clamp fitting around the boom with

a clevis pin through a backup plate and going into

a piece of 2” brass tubing (not pipe) shaped

as shown with a section of a nylon or PVC pipe fitting

used as a bushing. The clevis pin is held to the brass

pipe with a SS cotter pin. The white line seen is

the mast halyard. When the yard is lowered the gooseneck

is thus free to slide down the mast.

The above view is a

closeup of the halyard cleat that is mounted to another

piece of 1.25” of PVC pipe fitting. The area

just behind the cleat was sanded flat so that the

base of the cleat could mount to a flat surface. Flathead

bolts start inside the pipe with the nuts on the top

of the cleat instead of the other way around. To do

this I had to rout the countersunk holes in the cleat

flat for the nuts and lockwashers. The wingnut shown

locks a bolt that anchors the fitting in place, but

is easily removed so that the gooseneck fitting above

may be slid off the mast.

The above photo shows

my masthead fitting and a closeup of the clamping

device, where the two white sections tighten to clamp

this section of aluminum that is only 12” long.

Have you ever wondered

how to tighten the nylon locknut inside the tube when

an ordinary open end wrench, a box wrench or a socket

wrench either could not fit in or lie flat on the

tubes curved inner surface? To solve this problem

I took a piece of half inch steel conduit and with

a metal cutoff saw blade I cut a slot the width of

the nut. Now I was able to hold the nut in place while

I used the screwdriver on the outside.

While the mast is

in view, let me discuss what I did to modify it. In

the above photo I used a 12” tube at the masthead

in place of the regular 8’ inner tube. What

you don’t see is that I reinforced the 8’

mast with two 5’ hardwood spade replacement

handles that were spliced together and cut to the

remaining length of the mast (7’) These handles

were exactly the proper diameter and were held in

place by the bolt holding the halyard cleat. Now there

is no flex in

my mast.

This photo shows the

halyard fitting attached to the padeye that is clamped

to the Yard pole. Being clamped to the pole allows

me to relocate it so that I can find the ideal mounting

point while the inner tube is free to move.

Throughout this picture/story

you will see that I have used 1/8” “Quicklinks.”

Especially through the grommet at the Tack, Clew and

Head of my sail Its elongated shape allows the sail’s

grommet to be attached to the pole end eyebolts, and

may easily be removed. The size of the Quicklink used

is determined by the maximum opening between ends.

In a couple of cases I found that I had to grind a

few threads off the bare end in order to allow a slightly

thicker object

to be inserted.

So far I’ve

discussed the spars and it fittings, now we move to

the styrofoam hull. Unlike any other marine hull material,

one cannot mount anything to it with screws or glue,

so how do you mount the needed fittings?

In my opening paragraphs

I mentioned that the hull had two threaded rods corroded

to an aluminum bushing that had steel washers crimped

to each end of the tube. These bushings were molded

into the hull so that a shaft could be extended through

them.

|

|

In the bow, I assumed

that they had a cleat installed. In any case I found

a 2.5” wide by 1/8” depression. In this

depression I mounted a piece of stainless steel that

wrapped around the nose of the boat to a point 2”

beyond the shaft holes. Finding a small bow cleat

in my boat supply box I determined that I had to drill

and tap a 5/16” hole in its base. Then I drilled

two 5/16” holes in the ss bow plate directly

below the cleat and the plate on the bottom. Using

two flat head screws I mounted the cleat in the normal

fashion to the top of the bow plate with the tapped

hole in the cleat directly over the holes in the bowplate.

Within the shaft hole I inserted a new spacer tube

the length of which was slightly less than the hull’s

thickness. Using a stainless steel eyebolt with a

shaft long enough to go through the bottom of the

plate the spacer tube, the top plate hole and finally

tightened into the chock’s threaded hole. Thus

the bow now has a towing ring on the hull’s

bottom and a chrome cleat on the forward deck.

In the stern we needed

a replacement rudder and tiller and a similar stainless

steel mounting bracket had to be fashioned to hold

an aluminum rudder and tiller as seen in the following

photo

In the photo (Left)

above I show the stainless steel mounting plate that

was bent in my shop using my vise as a bending brake.

The aluminum kickup rudder is the gray object on the

right. A stainless steel shaft goes through the entire

object holding the rudder to the mounting plate. The

second screw up from the bottom locks in a piece of

neoprene rubber that is ½” thick with

a hole the diameter of the shaft. This prevents the

shaft from coming loose under any condition even when

turned turtle. The tiller being directly above this

shaft also prevents this pin from coming out unless

the tiller is raised past vertical. The bolt shown

in the photo below secures the mounting bracket on

top and below. It goes through the original shaft

hole.

The bar on top is the

tiller is an aluminum extendable tiller extension

as seen below.

The extension mounts

to the tiller by means of a simple key holder that

divides in two to hold your car keys on one ring and

your other keys on another ring. The lower right photo

shows the clamping device to adjust the length of

the extension handle.

The next item mounted

in the stern is the main sheet traveler as shown in

the next photo.

This simple device

allows the end of the main sheet to be clear of the

tiller, yet allows the boom to swing if you change

tacks. The block used has a steel sheave and the two

eyebolts have ¼”brass rods going through

the hull and secured with similar large washers and

nuts.

The last items are

in the center of the hull. – The centerboard

and the main sheet block.

In this photo (above) we see the centerboard baseplate

and the sheet block assembly. Originally this plate

was made of wood, but I’m not sure how it was

secured. My plates were made of stiff but thin sheet

aluminum By using a thin kerf blade I preserved the

center section without cutting the ends, so that by

cutting this 5/8” wide piece of metal in two

I created two legs that were bent down against the

bow and stern walls of the centerboard shaft. Thus

the bottom plate and the deck plate were mated together

with pop rivets inside the shaft.

Next I had determined that the best place for handling

the main sheet was in the center and not in the stern,

so I had to find a way to clamp the sheet in that

location. With the centerboard plates secured to each

other, I had a secure location to mount the main sheet

block.

This block was in my parts box and was perfect as

it had a V cleat built into it, but mounting the block

required that I create out of a strip of stainless

steel a special pad eye.

As seen above this padeye was poprivited not only

on top but also within the shaft wall also.

Next, problem was the centerboard and how to prevent

it from falling through the shaft. What I did was

to saw a 1.25’ deep cut along its top edge centerline,

and inserted a piece of aluminum T–Bar.

Using wood screws through the aluminum (pre-drilled)

from both sides the T-bar was locked into place. A

small padeye securing a brass ring. It allows the

raising of the board safely and with the ring lying

flat prevents toe injury.

The item saved for last was the sail.

The first thing I did before any restoration took

place was to search the internet. That was how I was

able to find the flyer about the boat and the size

and type of sail it came with. I learned that cloth

sails sold for as much as $500, and that was beyond

my means. This led me to Polytarp and Polysail and

then to Polytarp companies where I learned about the

weave the mil thickness UV protection, the cost and

the difference between the tarp size and the actual

dimension edge to edge that can vary as much as 9”

shorter.

I decided that while a sail kit might come with

more detailed instructions, I was going to build the

oldest sail in the world that is still being used.

The Lateen Sail.

The flyer said that my boat originally had a 7’

mast and 10’ boom and yard with a total sail

area of 60 sqft. With my purchased spars having a

capacity of 16’ long, I could in theory build

a lateen sail of 128 sqft. But that would be overpowering.

I searched the internet for building a lateen sail

such as the Sunfish, the Sailfish and the Funfish

as well as 9 other boats and compiled a list that

had the dimensions of the Luff, Foot, Leech and total

area. By simply adjusting the length of my poles and

the toppinglift length as a temporary substitute for

the leech, I could make any of the sails on my list.

I chose to make a sail that had a luff of 13’

and a foot of 11’ for an area of 61.48 sqft.

My reasoning being that the length of the boat was

11’ and a boom length of 11’. Therefore

the Clew would not overhang the stern if the Tack

was at the bow. All my fittings were adjustable so

I have the ability of moving the Tack to the stern

by as much as 2.5 feet and the same with the Yard,

thus giving me more or less headroom below the boom.

I followed the instructions of Dave Gray of Polysail

Int. and laid out my 14’ square white tarp that

cost less than $15, on my asphalt driveway (why do

we park on a driveway and drive on a parkway?) In

any case, I used cut-nails in the corner grommets

and stretched the tarp as tight as possible, yet the

fold line creases remained. These creases were to

haunt me later on.

Removing the spars from the boat (actually just the

boom and the yard which were adjusted to the proper

lengths required along with the rope representing

the leech length) they were laid down on the tarp

and positioned to allow my adding a curve to the foot

and luff.

My instructions said that 1/3rd the distance from

the tack should be the maximum dimension of the curve.

For the Foot it was 2” and on the luff it was

3.5 inches.

Using a dry marker pen (removable ink) I marked

the tarp along the outside of the tubing and the rope

(leech) and then removed the spars. In each corner

I drew two 6x6 squares of extra material that was

to be used for re-enforcing the corners.

Locating the maximum curve points I laid the corner

of a brick on those points and by using a 25’

x 1” tape measure on edge, I was able to layout

a perfect curve along the luff and foot. Again I used

the dry marker and marked the curve on the tarp, while

at the same time removing the original lines with

a damp rag.

With the help of my grandson, we now applied carpet

tape along the inside of my remaining lines, and tried

to make sure I had 100% adhesion. This was where the

fold marks in the tarp came into play as the tape

was not flat where it passed over the folds. With

a scissor I had to cut the tape so that the cut ends

would overlap each other and thus be flat.

Now with a sharp scissor we followed the outside

edge of the carpet tape and the two boxes of extra

material in each corner and cut out the sail and removed

the excess material.

So far the sail looked good with the curves on the

Foot and Luff. I now removed the protective paper

from the second side of the carpet tape and laid 1/8”

Dacron bolt rope on the inside edge of the carpet

tape starting and ending at the Tack where I left

an extra 12” of line. ¼ inch line would

have been overkill and using Nylon would have been

wrong as it stretches.

The next operation was the most difficult. I had

to fold the inside edge of the carpet tape over the

bolt rope and seal down the carpet tape without wrinkles.

Doing this and following the curve with the bolt rope

stretched and in the exact position was near impossible

to accomplish perfectly. By the way, I mention bolt

rope, do you know the only other rope on a sailboat?

The rest are all called lines. The one other exception

is called the Bell rope and is attached to the clapper

of the ships bell to make ringing easier. We all knew

that- right?

The next step was locating where to place the grommets

and starting at the Tack I marked every 18”

along the Foot and Luff and wrapped a 2’ wide

by 4” piece of vinyl tape around the edge of

the sail for added reinforcement. I didn’t but

most at this point should wrap the edges of the sail

in vinyl tape for a more finished look.

The next step was to finish and reinforce the corners

with the extra material held down with carpet tape

and with the end of the sail folded in so that the

corner grommet would be close to the bolt rope that

curves around at this point The corner is then finished

with vinyl tape leaving no exposed polytarp.

The last step was to install the grommets and here

I used ½” brass grommets in the corners

and 3/8” ones in-between.

As you see in the last two photos above, the Tack,

Clew, and Head were anchored to the spars with 1/8”

“Quicklinks” going to eyebolts with the

adjustable pole now used to stretch the sail tight.

My final idea was how to secure the sail to the

spars and still allow the sail to travel toward the

tack when I collapsed the boom and yard down to 8’

for travel and storage. My solution may be seen in

the final photos below.

|

|

Normally there are a couple of ways to secure the

sail to spars. We often see line laced around the

spar and through the grommets using one long line

or by using individual lines or electric cable ties.

I used cable ties but different from the designed

method. I went to Home Depot and purchased a package

of extra heavy 24” cable ties of nylon that

are 1/16” thick by 3/8” wide. I cut off

the head and cut the remainder into three equal strips.

I then drilled a 3/16” hole in the center about

½” in from each end and inserted what

is called aluminum “Post nuts” These are

items obtained in stationery stores for binding various

thickness reports into binders. Shown in the photo

are posts that are ¼” long, but they

are available in many size lengths and fit the standard

three hole paper. The left photo shows the normal

mounting position.

There remains but two tasks to complete the project.

One is to add a nameplate to the stern and the second

is to launch the craft and see if it sinks or sails.

Wish me a fair wind at my back, as I have never sailed

in a centerboard boat. My total sailing experience

has been in sail canoes with leeboards and keel sailboats

in sizes from 16’ up to 52’.

I sincerely hope that this article will inspire

others and give them ideas that they can emulate.

I wish to thank all who have posted to the internet

and those who posted on the “dwforum”

for their aid and knowledge.

Feedback:

In the article, Robert Goldwyn guesses that his Beachcomber sailboat is from the 1940s or 1950s. According to his papers, Lawrence Valentine Meyer (L.V.M. Associates), was building boats from 1960-1963 at his Michigan Fiberglass Company plant in Holland and then Borculo, which made Super Porpoise sailboats and Lake 'n Sea runabouts. He was employed by another firm from 1942-1959 making reinforced plastic products, but not boats. I remember his son, Lawrence Valentine Meyering, Jr., telling me that his family had moved to Coopersville after the boat plant was lost.

Thanks!

Geoffrey Reynolds

Director

Joint Archives of Holland

Hope College

P.O. Box 9000

Holland, MI 49422-9000

|