OK... so I’m a hobbiest at best. I’m impatient, a quick starter who loves trying something new, but hates the finish work. This was just one more side trip as the weather continues to keep me indoors in my relatively small workspace in the basement, while my half finished boat sits in the garage where normal people put their car.

Last week, I was at the local library looking through their collection of boatbuilding books to see if I could come across plans for a sculling oar.

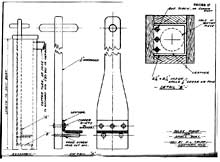

One of the books I picked up was “How to Build Small Boats” by Edson Schock, published in 1952. No oar plans, but what I did come across intrigued me. Plans for a bilge pump.

Ok..so I really hadn’t given a second (or first) thought to a bilge pump for my boat, and my personal experience with bilge pumps has been pretty much limited to using a sponge or small bucket to get rainwater out of the bottom of my canoe, but the design looked pretty straight forward and I had sufficient materials around.

Besides, Edson’s notation that “it will pump more water with less effort than most expensive brass pumps, and can be made in an evening” was even more appealing then a blue light special!

|

(Did I mention that I think I’m also a tad A.D.D. , cuz I thought I was going to work on oars!!)

click images for larger views |

The pump design needs to be attributed to F.L. Tripp, of Westport, Massachusetts. I’m not sure if F.L. is still around, but it looks like his family is still in the boat building business.

I put the pump together in a couple of relaxed evenings, using some Alaska Yellow Cedar, hardwood of indeterminate species and leather (for the valves) from some old snowshoe bindings I’ve since replaced. The plans suggest using ½” Cedar or Pine, for the box, with a hardwood handle.

|

|

| The only variance I made from the plans, was the use of SS screws to attach the leather valves (he called for copper rivets or bronze screws). |

I really wasn’t sure about what to use for the leather, but as I said, I had those old leather bindings just sitting there…..so they were sacrificed! (I knew I kept them for a reason.) The plans say that the leather should be flexible, but I’ve no idea how thick or what kind of leather they would have used. |

|

|

I also made the bottom valve as an insert – it fits in tight, but I can knock it back out if I need to replace the leather.

I made the top our of a scrap piece of Ocume and will fit it with a couple of hold down copper screws so I can easily take it apart and service/adjust the leather on the pump handle. |

Schock suggests that you discharge into the centerboard case or over the side with a copper tube or a hose. I haven’t actually taken the time to figure out exactly where I will put this in the Navigator, so the discharge will be sussed out this spring.

For those who are wondering – my pump is 18" tall and in my "test bail" I emptied a 5 gallon bucket in 45 secs with nice easy strokes (approx 30 stokes). A couple of manual pumps that I saw on the West Marine site rate the capacity in gallons/min based on 70 strokes/min.

Using that, capacity for my pump comes in at about 11 gallons per minute. Not great, if you compare against the $100 buck and up pumps, but it looks a lot nicer.  |

|

I’ve scanned the plans and have them posted HERE. If interested, you can probably also find the book through your local library. As Michael Connelly pointed out, most libraries are connected to regional networks and participate in interlibrary loan programs, making it easy to borrow books you might not think are readily available.

Tim Ingersoll |