| Send

items to chuck.leinweber@gmail.com

for inclusion here next month.

Fred

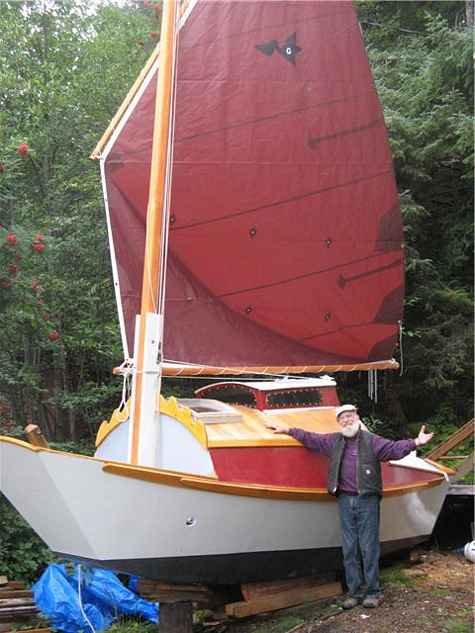

This is the first of a several part series. It will be the story of "Brooke's Last Boat." I'm Brooke, a 75-year-old guy who has been messing with boats for all of his adult life. The planning for The Last Boat started three or four years ago soon after the day when I'd gotten stuck, again, in the bilge of the 60-year-old Bill Garden cruiser and Wendy had to pull me up by the back of my belt. It was time to admit that the time had come for a different boat. The old girl was beginning to get ahead of me anyway and I sure as hell didn't want to be the guy who let her go to pot. My 75-year-old hip was shot, the knees not much better and doing the necessary maintenance had stopped being the mostly fun activity that it used to be. On top of it all, after cruising the Inside Passage as a couple for several decades and several boats - all sail until the Garden cruiser - we had settled out in an isolated coastal community in SE Alaska and Wendy found that she would rather be out fishing from her skiff than cruising. It was time to think of what sort of boat would meet me needs now.

This is wonderful sailing country with long bays ending in tidal flats, often separated by stretches of challenging open water and weather that keeps you on your toes. It is mostly well protected from the serious stuff that arrives straight from Japan. For reasons that I'll get into later, I decided on a dory pram style that would be just big enough to give me standing headroom and stable enough to be handled safely by someone of limited agility. Three models of increasing accuracy convinced me that it was a realistic goal and I built FRED over a two-year period ending this past spring. I was well pleased with him and was primed to spend the entire summer just past poking around the twenty-mile long inlet where we live and getting things sorted out for more adventurous stuff next year. It was not to be.

This is primitive country in lots of ways, the community has a nice small boat harbor and a tidal grid but nothing like a launch ramp or a lift. We took FRED to a flat beach at low tide and waited for the water to lift him off the trailer. After two days of calm conditions, it began to breeze up just he was about to float off the trailer. It was a long flat beach, though, and I had plenty of room so was not worried.

To say that he rolled badly does not describe his alarming lack of stability. The wind continued to rise and there could be no thought of raising the sail. The launch beach was close to the harbor and we got him to the dock and secured without mishap but it was probably the worst day of my sailing life. Two years of near-daily work, in a community of 75 people where everyone had watched the building progress; most had watched the launch and my new boat didn't float. I had simply gotten him too narrow. For that first few hours I seriously considered a bonfire. Either that or chop the mast off and call him a power boat. It looked as if I had two equally bad alternatives.

In the end we took him home, I cut him in half right down the middle, spread the halves apart by two feet and I am just now in the last stages of reassembling him as a wider boat. It has been a completely engrossing process that illustrates the unique possibilities of plywood, the pitfalls lurking for the "intuitive" builder and, hopefully, an encouragement to others.

In subsequent installments I will describe the design philosophy that lead me to FRED, some of the building techniques that stood me well and, if all goes well, a report on a successful outcome.

Brooke Elgie

Tenakee Springs, Alaska

Part Two of this story coming soon...

Sparrow Progress Photos

Putting final paint on Sparrow's hull. Maybe a month from completion, still have to fabricate the spars, etc.

This is a one-part enamel - Interlux Brightside Enamel.

I start by applying two coats of a high-build primer, Interlux Pre-Kote Primer (in this case, Gray). Sanded between coats, and no "tip out" when applying the primer, just leaves streaks.

Then roll on the finish coats, 2 or 3, and tip out to remove bubbles. About the best finish you can get without spraying, which I am going to switch to soon.

Bill

AF3

What does an AF3 when there is over three feet snow everywhere and about two and half feet ice on the lake? It hibernates! But what does the sailor meanwhile? Who knows, maybe builds something with an outboard engine?

Markku

Foam Boat

This is the rest of the story about the foam boat we built a while back.

I built this hull and Jim finished the rest. We all thought that it would be unsinkable but we've never actually tried, till today. The hull is two inch foam glassed inside and out with enough glass to build a battleship. Two layers of 1708 covered with two layers of 10 oz cloth inside and out.

In addition the bottom front has a layer of kevlar Laylah and I put it (#8) in the water and pulled the plug. About four inches of water came in then stopped. If we had been sailing we wouldn't have even slowed down. I couldn't turn it over in the water so I put the plug back in and bailed water into it.

You can see how high it floated full of water. I took a picture, water up to the bottom of the yellow rail and pulled the plug. In about a half hour the water was out to about four inches deep. I bailed it out and put it back on the trailer.

This is the boat I want. Super strong, very fast and totally unsinkable, even if you cut it all up. The boat have if you're looking for all this and safety. Jim is about finished with his new boat and will sell this one for $5000.

Dave Lucas

It's Always Summer Somewhere

We dream of warm days, gentle breezes and sparkling waters, of days off when work doesn’t call, of times when all the obligations are fulfilled and the bills paid and we can go sailing.

I read the stories and letters told by northern hemisphere sailors during our winters, and although we don’t have the snow and ice that many parts of the world do, I’m not immune to envy. But here and now in New Zealand we’ve escaped the bad weather that has so damaged Australia, we’re having days that hit 80deg F every day, 12 to 15 knots of wind every day and the blue skies are made even more blue by contrast to the few fluffy white clouds.

Dave Perillo has had his AWOL design “Medusa “ for two summers now, has the rig pretty well tuned up and is out cruising. Our friend Paul Groom is sailing in company in the 22 ft long keeled Woolacott design “Carol” he’s restored since selling his Pathfinder Varuna to Frank Bates.

I’m hoping that Paul will send some photos and a story about the restoration of this lovely old vessel to Duckworks to show us what a major job the restoration was, and how well its been done. Remember this is a guy who not so long ago was phoning me a couple of days a week to ask questions about building a Seagull, and then the prototype Pathfinder. He did really well on both and the lessons learned must have stuck as the “Carol “ is beautiful.

Now that he’s out on the water and sailing again, he’s got his camera and has taken these two lovely shots of Dave P's “AWOL in action, they’re racing and there wasnt much in it. Dave tells me Paul got there first, but not by much.

So, for those of you who are looking forward to summertime, here are a couple of shots from where it really is summer, just as a pick me up to hold you until the world turns a few more time and the sun begins to warm you again.

John Welsford

Marine designer

Pic by Paul Groom

Sculling Boat

Peter came by today to try out his new toy. You remember Pete, he's the other one who can't pass up any old boat he comes across. He did this in college so he managed to stay upright. I wouldn't have lasted two seconds in this thing. It's 25 feet long and about eight inches wide and weights nothing. When he pulled it hard the whole thing seemed to leap out of the water. Now he needs to appease his wife so he'll sell his ComPac 19 cheap.

David Lucas

McMurdo launches innovative Personal AIS Beacon at Miami International Boat Show

McMurdo will launch the Smartfind S10 Automatic Identification System (AIS) Beacon at the Miami International Boat Show in conjunction with new US Distributor, Survitec Survival Products Inc., Booth No.065. This innovative personal safety device incorporates both AIS and GPS technology which, when manually activated, gives precise location information to aid the recovery of persons in difficulty at sea. It is designed to be carried by divers, boat crews, or anyone who spends time on the water for leisure or work.

Waterproof, buoyant and compact, this unique device can make all the difference in a search and rescue situation. The chances of being rescued are greatly increased thanks to its ability to transmit both AIS and GPS data to all AIS receiver-equipped vessels and land based VTS (Vessel Traffic Services) stations within a 4 mile radius. The first of its kind, theSmartfind S10 AIS Beacon features an inbuilt high precision GPS receiver, and transmits target survivor information, including structured alert messages, GPS position information, and a unique serialized identity number. Bearing, range and location information are accurately transmitted and displayed on the AIS receiver or plotter screen, giving potential rescuers all the information they require to carry out swift retrieval of an individual.

The Smartfind S10 AIS Beacon will transmit continuously for a minimum of 24 hours, regularly updating position information, and has excellent longevity thanks to its five year battery storage life. Waterproof to 60m, it also features a flashing LED light to assist with visual fixing and night-time location. Measuring 9.7” x 1.7” and weighing just 5.29oz, it is small and light, making it easily portable. The beacon is easy to activate, with a simple two-stage activation function that can be used, even when wearing gloves.

www.mcmurdo.co.uk

The Smartfind S10 AIS Beacon will be available from Q2 2011, with a retail price of 349US$ + TAX.

This device has not been authorized as required by the rules of the Federal Communications Commission. This device is not and may not be offered for sale or lease, or sold or leased, until authorization is obtained.

Kannad Marine launches revolutionary SafeLink R10 Survivor Recovery System at Miami International Boat Show

Kannad Marine will launch the SafeLink R10 SRS (Survivor Recovery System) at the Miami International Boat Show in conjunction with new US Distributor, Survitec Survival Products Inc., Booth No.1642. The SafeLink R10 SRS is a world-first personal AIS (Automatic Identification System) device, designed to be worn by individuals and activated to assist with recovery in a man overboard situation.

Worn on a lifejacket and activated by simply sliding off the safety tab and lifting an arming cap to deploy the antenna, this unique product sends structured alert messages, GPS position and a special identity code directly to AIS receivers within (approximately) a four mile radius. The accuracy of data is guaranteed thanks to the unique inbuilt high precision GPS receiver which updates every 60 seconds. With precise location, bearing and range data given, fellow crew members or nearby sailors’ AIS enabled receivers have all the information they need to locate the position of the man overboard and effect a speedy recovery, greatly increasing chances of rescue.

The R10 SRS can also be professionally fitted to a lifejacket so that it automatically activates whenever the lifejacket is inflated. A flashing LED light aids location at night. The R10 SRS is guaranteed to transmit continuously for 24 hours and has a seven year battery storage life. It is made of ultra durable ABS, and is waterproof to 5 metres.

With dimensions of 0.5” x 1.8” x 4.7” and weighing in at just 4.23 oz, this compact and lightweight search and rescue locating device is the must-have personal device for all safety-conscious sailors.

The SafeLink R10 Survivor Recovery System is supplied with attachment clips and lanyard, it will be available from Q2 2011 with a retail price of 349US$ + TAX.

https://www.mcmurdo.co.uk/

This device has not been authorized as required by the rules of the Federal Communications Commission. This device is not and may not be offered for sale or lease, or sold or leased, until authorization is obtained.

Model PDR

This is just a few PDR's (M) miniature's that have been build by Rhonda and Crew. Thought you might like to see them.

Jack

Pathfinder

I am Vram from Istanbul. I bought plans of pathfinder last fall. I say proudly that I am halfway in the construction of the boat. I finished the stringers without a problem and I will start planking. You can see the status of the boat in the attached picture.

Thanks for your interest. Vram Babayan

Model Catboat

Remember a while back when I sent these pictures of a model Jay Bliss made for an 18 foot funky catboat he wanted to build? Well here it is, almost. A good example of how you can build a boat with a little inspiration and not too much over thinking. Anyone can follow a set of detailed plans but only a genius can make it up as he goes along. Looks like Jay's taken it to the extreme except maybe for the rig. I told him that we had a 40 foot tall aluminum mast with sail to go with it for this boat and he turned me down. Maybe I can get Tom Shephard or Mike Wick to put it on a big Tuckup, that's another boat that'll get you wet. Too bad these homemade designs usually turn out looking like Bolger boats. ( I can see the hate mail already) You see a lot of these kind of things at Cedar Key in May.

https://traditionalsmallcraft.com/index.html

David Lucas

Lucas Boatworks and Happy Hour Club

(941) 704-6736

Scarab 18 Folding Trimaran

The boat I loved building is finished at last. It is on the trailer in the yard waiting for the weather to change so we can see if it floats. The kids are joking about us being flooded in saying we have the boat what's the problem. Ray Kendrick and I make up Team Scarab a business SE Queensland that sells boat plans. At present we have 9 trimaran designs aimed at the home builder. I usually occupy myself with the web site and book keeping but when Ray had to work away from home in order for us to survive I decided to build a boat. I had helped on other projects before but this was my first solo effort. Ray designed and fell in love with an 18 foot folding trimaran. I have developed an allergy to epoxy resin so I wanted to build the boat using foam and polyester resin. The boat is built using flat panels over a male plywood frame. The boat can also be built using plywood laminated panels.

The foam was joined to the right length and glass was laid over the length. The resin was spread using a flat drywall spatula. We use peel ply over the resin to give a smooth finish to the laminated panel. The panels for the boat were cut out as you would for plywood joined to the frame with drywall screws and taped with fibre-glass tape. It was very quick to join all the panels. It was turned over and taped inside.

All the bulkheads and centreboard case and beam supports were added.

The deck and cockpit were added covered with glass.

The two floats were built in the same way. It took only a day for each float to be joined to the temporary frame and taped on the outside.

The bulkheads were added and support for the deck. The beams can be made using a mould that can be knocked up from plywood or form ply. Add the specified number of layers of glass.

The beams are joined to the floats.

The boat was faired and painted. At this point Ray came home and I was happy to let him finish off his boat. The windows added.

The interior was painted and cushions added for comfort.

The folding mechanism was added to the main hull to join the beams and floats.

The trampolines were made using seat belt webbing which turned out to be remarkably strong.

Now the boat is waiting to be launched while we have the most rain Queensland has seen for 50 years.

This will not be my last boat; I have the building bug. It's just trying to decide what I want to build next. This boat was built in less than 500 hours and it cost about $10,000 AUD without rig. We used a modified tornado catamaran rig and it should fly. It would have been less in plywood but the resale value of foam is higher.

For our other designs and more pictures see www.teamscarab.com.au

Fran Sneesby

Just for fun....this made me laugh

This is for all you paddle boaters, you'll love it. In fact, all of you will. Be sure to do this, Laura is one of my favorate girls !!!

1. Go to Google Maps and click get directions.

2. Write U.S.A. as your start point.

3. Write Japan as your destination.

4. Go to the 31st point on your route.

5. Laugh.

[Here's the result if you got lost.]

Dave Lucas

Applications Being Accepted for 2011-12

The Northwest School of Wooden Boatbuilding, located on the water in Port Hadlock WA on Washington’s beautiful Olympic Peninsula, announced today that it has begun accepting applications from students for the 2011-2012 academic year, which will begin in October 2011.

Application forms may be found on the School’s website at www.nwboatschool.org

The School’s major courses, described below, are accredited by the US-based Accrediting Commission of Career Schools and Colleges (ACCSC).

The School’s mission is to teach and preserve the skills associated with fine wooden boatbuilding and other traditional maritime arts with emphasis on the development of the individual as a craftsperson.

Locally known as “The Boat School”, the School carries on the vision of its founder, Puget Sound area Master Shipwright Bob Prothero, to teach and preserve the skills and crafts associated with wooden shipbuilding. 60 students are attending the Boat School this year in four major areas of study.

The School's mission - teach and preserve skills

Whitehall

The School strives to impart sound, practical knowledge in traditional maritime skills, using wooden boats as the training medium.

Students range in age from 19 to 75. About fifteen percent of the School’s nearly 60 students this year are women, and thirty percent of the School’s students are retired people.

The School’s waterfront heritage campus includes four boat shops including a brand-new 6,300 foot shop opening in March 2011 in addition to the School’s administrative offices and an extensive library. Northwest Sails, which is associated with the School, maintains a large sail loft on the School’s campus, which is used for sailmaking and rigging instruction. The School also has welding and blacksmithing shops, and partners with the community boatbuilding program in a dedicated on-campus shop.

Many Boat School graduates work across the Pacific Northwest and the country where their craftsmanship, creativity and artistic talents enhance their communities.

Programs include 9 month diplomas and 12 month Associate Degrees of Occupational Studies in Traditional Small Craft, Traditional Large Craft, and Contemporary Wooden Boatbuilding. The School also offers a 3 month Certificate program in Comprehensive Sailmaking and Rigging and offers shorter summer workshops as well.

A typical day at the Boat School runs from 8am to 5pm. Students spend 8am – 10am in the classroom and from 10am – 5pm in the shops.

During the first semester, all students take the Basic Skills course. Students gain familiarity and hand tool expertise through a series of progressive exercise projects which include a series of joints, a dovetailed toolbox, a wooden plane, and a half model. Classes and practical skills in drafting and lofting culminate in student-built wooden skiffs by the Holidays.

From January through mid-June annually, students work in teams to build at least two and more often three progressively more complicated boats in each of the major classes.

Summer Repair and Restoration and well as Interior Yacht construction classes round out the academic year, which concludes with graduation in mid-September.

The Northwest School of Wooden Boatbuilding is accredited by the US-based Accrediting Commission of Career Schools and Colleges (ACCSC) to grant:

- Diplomas in 9-month Traditional Small Craft, Traditional Large Craft, or Contemporary Wooden Boatbuilding;

- Associate Degrees of Occupational Studies in 12-month Traditional Small Craft, Traditional Large Craft, or Contemporary Wooden Boatbuilding

Interested people may download application forms from the Boat School’s website or contact the School on Washington’s Olympic Peninsula at:

The Northwest School of Wooden Boatbuilding

42 North Water Street

Port Hadlock WA 98339

360-385-4948

www.nwboatschool.org (and on Facebook)

|