Custom Search

|

|

| sails |

| plans |

| epoxy |

| rope/line |

| hardware |

| canoe/Kayak |

| sailmaking |

| materials |

| models |

| media |

| tools |

| gear |

|

|

| join |

| home |

| indexes |

| classifieds |

| calendar |

| archives |

| about |

| links |

| Join Duckworks Get free newsletter Comment on articles CLICK HERE |

|

|

| Going 3-D |

by Daniel Roberts - Salisbury, North Carolina - USA |

Lagniappe'Duckworks readers are familiar with the term and I did it in five work days. Here is the whole building sequence up this point.

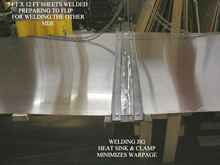

With a full face shield and hear muff hearing protection, all I heard was a low hum.

I placed temporary 2 x 4’s to widen the table and pulled the sides out beyond the bottom in preparation for standing it all up.

My friend, Barry, stopped by and helped me stand it all up.

It took maybe 15 minutes what with all the fiddling to square it up. More of that as I progress. The SternIn the movie “Star Trek, The Wrath of Khan” Captain Spock coaches Admiral Kirk saying that although Khan is highly intelligent, he is prone to two dimensional thinking. So it is with some boat builders and designers who work on drafting boards and even 2-D CAD programs. Nowadays, even in the industrial world, programmers who set up CNC machines get paid more if they are able to Program a 5 axis machine as opposed to others who can only program in 3 axes. Five axis machines such as machining centers are used to produce such things as submarine propellers and turbine blades which have very complex shapes. For the boat builder this can come into play when trying to build a boat with a tucked under round stern. Without using a 3-D CAD program it’s next to impossible to draw what you want. The photo on the cover of Ruel Parker’s tome “The Sharpie Book” was used in an article in WoodenBoat Magazine several years ago (or maybe it was “The Small Boat Journal”). In it the author explains his frustration with trying to design a single plywood panel that would give him the round stern he wanted. He finally gave up and went with narrow vertical stave construction; nailing the individual staves to two horizontal frames at the shear and chine lines. That’s how the Sharpie builders of old did it too. Building the round stern in Aluminum can be done in two ways: a true arc or a segmented arc. However we first need to mock it up to see how it will look in the end (no pun intended).

For the actual pattern, I’m going to the home store for some plastic laminate. It’s thin enough to bend to the shape for clamping and take-off. The Aluminum will have to be rolled. Including the stern but without the gunnel, the length overall is now 24’ 8”. Probably another inch… I think it gets tedious from here and progress will slow.

Dan Roberts

|