Custom Search

|

| boat plans |

| canoe/kayak |

| electrical |

| epoxy/supplies |

| fasteners |

| gear |

| gift certificates |

| hardware |

| hatches/deckplates |

| media |

| paint/varnish |

| rope/line |

| rowing/sculling |

| sailmaking |

| sails |

| tools |

| join |

| home |

| indexes |

| classifieds |

| calendar |

| archives |

| about |

| links |

| Join Duckworks Get free newsletter CLICK HERE |

|

|

| The 12 ft. Leland Lake & The John Duk |

by Warren Messer - Seattle, Washington - USA |

The 12 ft. Leland Lake

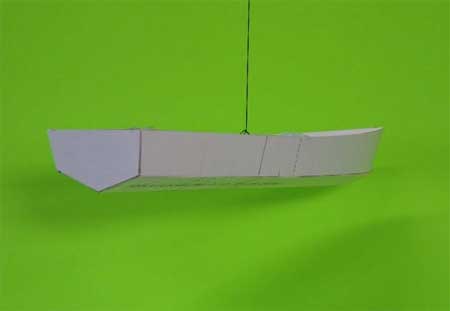

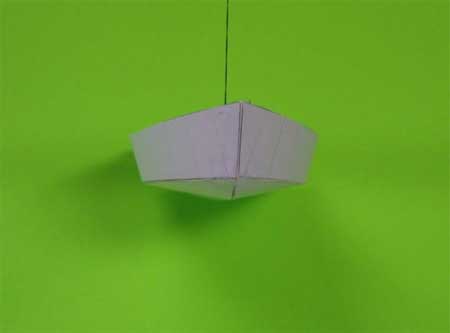

After designing and building the 8ft Nuthatch Pram, I thought that I would modify the design to a standard "V" bowed hull to see what it would look like. I was surprised to see that the hull design could be modified this way, and the first model came out looking pretty good to me; but I had other hulls in the works, so this one sat on a shelf for a few years. I caught up with some of the projects I was working on and turned my attention back to this hull and tweaked the design in the transom area, and fixed the curves leading into the bow point of the two bottom panels at the keel line. I also stretched it out to 12ft (flat) so it will just need a full and a half sheet of plywood (with a Payson Joint) to make it. This design could even be lofted down to 8 or 10feet, and up to something around 20 feet or greater. I would modify the "V" of the keel to be even more pronounced (deeper) on the forward section of these larger hulls, and add standup steering stations to the designs.

This design still has curves in the hull panels upper and lower edges that will need to be lofted up, but there are sections of straight edges on each of them too. This will make the hull a little easier to loft up, but you will still need to layout the curves on the bow ends of the side and bottom panels. The keel line is straight from the transom up to about the 8ft mark near the bow, and then the curving starts up to the bottom edge of the bow. I took some time with the design so the "chine edge" will look like a straight line when the hull is in the water, so it should look good with the slight dip in the rails at the middle and the rise of the rails to the bow. It has a bit of classic Lobster Boat look to it and should be good in wind and waves. I also made the transom 20" high for safety; so you will need a long shaft OB motor. This hull design is mainly for those that want a fishing style hull, and need a seating layout that is normally used with an outboard motor. I have moved the rear seat off the stern so you may control your outboard motor's tiller more easily.

I have gone to using the "enclosed pyramid" (with watertight hatches) style of seating in all my designs for safety reasons. After reading a story, with photos, dealing with the deep water self rescue of a brand new "traditional open interior" small boat design, and they couldn't; I will no longer include drawings or instructions for old style wooden plank seat interiors. Your safety, and that of your family members is more important to me, than any negative comments about my hull interiors. This hull as designed, has around 5+ cubic feet of extra positive flotation build into the enclosed pyramid seating. That's over 300 pounds of extra support, along with the wood in the hull. The two handle/steps on the stern are there to help you or a loved one, get back in the boat again if needed. Always carry and wear, a life jacket adequately sized for you and your guests, and be sure they are in good condition at all times.

This is a design that I have not built a prototype hull to test the lofting from the design build plans, but after tank testing other previously built hulls, and comparing them with the launch photos and the way they sat in the water after being built, I'm confident that the waterline shown will be correct. I have also found that there are very few "tweaks" that I have had to make to any design while building from my computer generated plans. Any errors are usually in the 1/16" +/- range at a couple points during the lofting and curve smoothing stage. I would expect no problems during construction.

***** 14ft John Duk

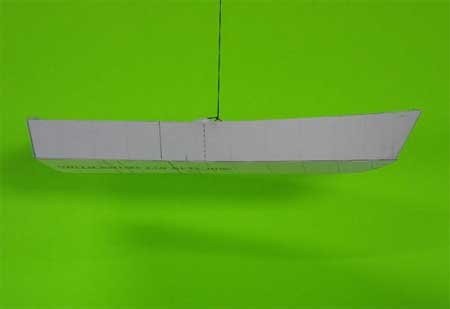

This hull is a continuation of one of my very first designs. When I was working up the plans for a 10ft fly fishing hull for a launch customer, a version of this hull was the first model of the Hudson Springs Pram. When I showed the 10ft version of this hull to him, he wanted a "flatter bottom". I didn't really want to design a flat bottomed boat, so I made the flat part wider. After about three versions of a wider flat part, I through my hands in the air and made it all flat. I don't like "all flat" bottomed hulls, because of their tendency to remain stable until they flip with minimal warning, and no time for recovery. I always liked this style of hull and kept a model of it in my "bone pile" of hull design ideas.

I liked the narrow flat part of the bottom of the hull, as it gives a bit of stability, and keeps the hull flat when you beach it to get in or out. The "chine edges" between the flat bottom of the hull, and the two curving lower side panels also acts as a stiffener for the bottom. A pure flat bottom would need supports between the bottom and side panels to keep the hull bottom from oil canning. The narrow flat area can also be strengthened by going to a thicker plywood cross section than the rest of the hull. More strength can be added to the hull by the choice of the seating style you select. In the build and study plans I will give you some options to think about for your hull.

One more thing that I liked about not having a completely flat bottomed hull, was that the U. S. Coast Guard limits the horse power on them. By having a bit of drop/modified V to the bottom, I could use a larger OB to power it. If it was a center console hull, the max HP could go up even more, but their rules cut back on max HP when the operator is sitting in the transom area, even though this hull has a 20" transom height. The transom height as designed will require a long shaft OB, but if you have a shorter OB, you can cut the center of the transom down to fit your short shaft OB. Just make sure that you have a 20" high false transom ahead of the motor mounting area of the transom to keep water out of the hull if you come into the dock to fast and get pooped. Or from large following seas and waves. Higher is always better.

For those readers out there wondering about the name, it's a play on "Who is John Galt", as in what is a John Duk? It's not quite a Jon boat, and a bit different from a traditional duck boat too, with it's semi flat bottom, but it should be a good boat for fishing and hunting, and a lot cheaper to build/own than going out and buying an Aluminum boat. At least you can fix a wooden hull a lot easier than patching a hole in a metal one. The hull can also be sized up from the 14ft it is now to a bigger boat, if there is interest in a bigger hull. I have a 16ft version in the modeling stages now. Have fun printing out and making the model for this hull. I added some graphics to it to get your mind thinking about all the fish and fowl you can go after. Thanks Again |

To comment on Duckworks articles, please visit one of the following:

|

|