|

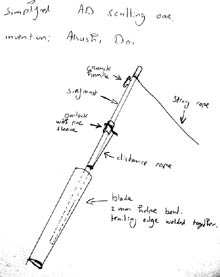

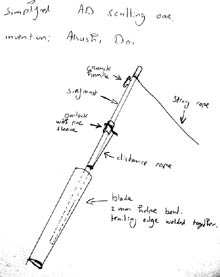

For my little trimaran I use a very clever sculling method, invented by Atsushi Doi. You can see all his information by googling/youtubing AD sculling.

This year I participated in the Dorestad Raid, a sail and oar event in the Netherlands. I noticed I could keep up with most of the rowers, and that the other participants were surprised how well the AD oar could drive my boat (also backwards – very practical for docking).

I already made several versions of the oar, and I think now I have found a handy method for making such an oar.

The “real” version is beatifully carved from wood, with a curved handle (this bend produces automatic rotation of the blade).

My version is made from an old windsurf mast, with a blade made of a sheet of 2mm HDPE bent around the mast and a “cranck handle” on top instead of the bent loom.

This produces a strong, light, easy to make, cheap and maintainance free oar which seems to work good.

I hope the attached pictures speak for themselves, especially if you combine them with the original information/video's from Doi.

A few notes :

- The measurements shown are from my oar, and are all guestimated. They can be used as starting point.

- Plastic sheet was difficult to find (and expensive!) untill I found the right supplier. HDPE 2mm thick is good, use the black version for UV resistance

- I plastic welded the trailing edge (you need welding rod and a special piece for your heat gun). I folded the sheet, clamped the ends flat together with the underlying sheet sticking out a few mm, welded and used a planer to smooth the edge. HDPE is easy to plane.

- If you cannot weld you can probably sew the trailing edge together with a lot of small holes and strong thin wire (like kite line)

- Another option might be to use ABS plastic, there was an article in Duckworksmagzine about welding ABS. Or use something else that's bendable in a fair curve.

- My oarlock uses a PVC pipe slit lenghtwise, and a rope to prevent the oar sliding down too much. This is smooth without noticable friction.

- My cranck handle is a plastic cleat tied with bycicle inner tire, but you can use all kinds of handles. A bit more elagant wouldn't hurt ;-)

- The “strong rope” is the secret why this oar works so good. It takes the forward force of the oar, so you only have to work the oar back and forth sideways. The rest goes kind of automaticaly.

- Normally, you would have the spar (mast) at about one third of the depth of the chord of the foil. For this oar it should be more forward, or else the oar is overbalanced and starts to behave unpredictable.

Greetings from Amsterdam, and if you experiment with the oar Atsushi Doi is interested to hear what you have found out.

|

. |

|

. |

|

. |

|