Custom Search

|

| boat plans |

| canoe/kayak |

| electrical |

| epoxy/supplies |

| fasteners |

| gear |

| gift certificates |

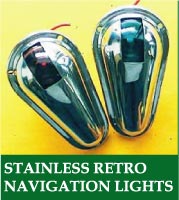

| hardware |

| hatches/deckplates |

| media |

| paint/varnish |

| rope/line |

| rowing/sculling |

| sailmaking |

| sails |

| tools |

| join |

| home |

| indexes |

| classifieds |

| calendar |

| archives |

| about |

| links |

| Join Duckworks Get free newsletter CLICK HERE |

|

|

| Just Scraping Along |

At some point during my apprenticeship I started using a homemade scraper given to me by an old shipwright. The scraper was made from a six-inch long section of a 3 inch wide power hack saw blade and the teeth on one edge of the blade were covered with a few strips of funky duct tape so they didn’t dig into your hands when scraping. This stiff old scraper was about 3/16” thick and impossible to bend or flex, but once you got the blade sufficiently sharpened it stayed sharp longer than any scraper I have owned since—the problem was it took 15 minutes of vigorous and careful work with a new sharp file to get the darn thing sharp. And you had to be careful to file perfectly straight across—a flat 90 degree angle, which provided 2 sharp edges. But after all that it did work well, not only to strip paint and varnish but also to fair and shape. I found myself using this tough old scraper more and more and sandpaper less and less.

As years passed I almost eliminated the use of sandpaper in my own shop. I used to keep six or eight different grades of sandpaper, and like we were all taught, when finishing wood we worked through the numbers starting with rough and finishing down to fine. I kept my stash of sandpaper, complete sleeves full of all the different grades, on special shelves located high on the wall behind the little Jotul wood stove, because without the drying effect of the wood stove the humid northwest coastal climate turned the sandpaper damp and useless in a few weeks. Not only was the stuff expensive it required special care, and while sandpaper has its special uses, the scrapers still worked better for most applications. Once I realized the potential of scrapers I started looking around for other types. I used the edges of old plane irons, the blade of wide chisels and slicks and the flat blade of a lightweight Japanese hatchet that fit my hand just right. All worked to a degree, and some worked very well for specific jobs, but for convenience I eventually graduated to thin rectangular scrapers for most jobs. Rectangular scrapers had advantages. All four sides could be sharpened with a fresh file in about 2 minutes, which provided 8 sharp cutting edges. They could easily be filed to accommodate a slight convex or concave shape and thin scrapers could even by bent or sprung slightly in your hand to accommodate a particular shape. Just so they wouldn’t disappear in the bottom of my tool chests I drilled a small hole in the middle of each one and stuck them up on the wall so I could find the one I wanted.

Over the years I’ve accumulated a variety of scrapers but I still mostly use the traditional rectangular cabinet scraper. I have over a dozen much used rectangular scrapers in my toolbox and a variety of other types that still work well for specific jobs. Some have been filed down almost to a small sliver and others have been shaped to accommodate concave or convex shapes. I’ve tried scrapers with attached handles and blade inserts, and I suppose they might work for some applications but I usually prefer the versatility and convenience of holding a rectangular scraper in my hand. Its easy to flip it around to a fresh sharpened edge, and when using a really sharp scraper I seldom need the leverage provided by the handle. An attached handle does allow you to bear down harder, and they work well if you need that leverage. Scrapers with handles also won’t reach into small spaces as easily as a hand-held rectangular, plus you’re working with only a single edge.

Scrapers can be used for both fairing and smoothing, and it's worth repeating that the critical factor is to keep them sharp. I used to carry my scraper kit around in a canvas bag in which I kept a half dozen of my favorite scrapers of different sizes and shapes, 2 or 3 sharp fresh files in their protective plastic envelopes and my trusty little heirloom “clamp-on” vise. I can clamp the little vise to the edge of a table or sawhorse and sharpen all four sides of a scraper in about 90 seconds, which provides 8 fresh sharp edges. If you don’t have a vise you can also use C-clamps to hold a scraper securely in a vertical position to be filed, but the hassle of fiddling with the clamps will keep you from sharpening as much as you should. You also need fresh files—those old beat up files in the bottom of your toolbox won’t cut it. And if you find it necessary to really muscle the scraper to remove difficult spots of varnish or paint you may also need a pair of leather gloves to protect your hands. Once you start using scrapers you’ll find more and more uses for them. They’re great for stripping off built-up layers of tough old clouded varnish from cap rails and hatch covers, and then they’ll take off a very fine controlled shaving of weathered or stained wood in preparation for a new coating of varnish. They’ll level a finely fitted scarf joint in a teak caprail, take a controlled shaving off the rail and stiles of a cabinet door, shave down opposing or run-out grain without lifting either side, and they can also work well for final shaping of carvings. SCRAPERS AND EPOXY Scrapers work well in many traditional woodworking applications, but they function particularly well when building or modifying with epoxy, on flat or curved surfaces. I don’t know what else but a scraper would work for the first cleaning of plywood panels after the initial saturation coating. That first coat of epoxy will raise splinters, there will likely be bubbles from outgassing, lint and kamakazee bugs will raise craters that must be removed for a smooth final finish—not to mention possible drips and runs--and I can’t image using anything but a sharp scraper. Sandpaper will gum up and scratch the surface and if you try to hand sand without using a block you’ll eventually discover all kinds of gouges as you continue finishing the surface. A scraper just “scrapes” off the high spots---duh!---and successive coatings will fill in the low spots. Dealing with outgassing and bubbles can be a nightmarish situation if you bring cold plywood out into the sun or into a heated shop and immediately apply epoxy. The trick is to heat the wood beforehand, then allow the temp to be dropping as the epoxy kicks. Makes a tremendous difference. Maybe theres not much you can do about those gnats and flys that appear as soon as you’ve carefully laid on that coat of epoxy, but outgassing can be controlled to an extent. Second and successive coatings of epoxy will go on smooth and silky, expecially if you apply it with a thin foam roller for consistent coverage then tip it off with a foam throw-away brush, and I still run a wide scraper lightly over the surface to catch any imperfections. I also use scrapers to take down the raised “selvage” edge of glass tape and by dragging a sharp scraper lightly across a sheathed surface it will highlight areas of the cloth that need more epoxy to fill the weave. You’ll be surprised how effectively a sharp scraper will take controlled shavings off a hard ridge of cured glass tape. When I graphite the bottom of one of my small boats I scrape after each coating to highlight and shave off drips and show me low spots where I can roll on more epoxy/graphite mix. In this manner the bottom gets slicker and smoother every time it gets scraped and at the end of each season the wear pattern on the bottom also shows where more graphite or hull reinforcement may be needed. Epoxy fillets are cool looking and useful on wood and fiberglass boats, but they require some practice to make them really nice. What I hate to see is a hand sanded fillet that looks “worked”—they never look right—so I try hard to make fillets that won’t need sanding. I file down a scraper corner to the radius I want—and then I use that scraper as a paddle to apply the fillet. Then I use the same scraper to “scrape” the cured fillet. Doesn’t gouge like hand sanding leaving that worn-out look, and still cleans up the inevitable bumps and lumps on the fillet, making it ready for a final seal coating of epoxy and then paint or varnish. When you use a scraper, hold it perpendicular to the work surface with one hand on each side. Tilt it slightly toward you if you’re pulling the scraper, and away from you if you’re pushing—works both ways so you can scrape down a large area quick with a minimum of passes. If you encounter a really tough area, sharpen the edge, slip on a leather work glove and hold the scraper like a chisel. Use the smaller ends of a rectangular scraper for difficult work as it concentrates force in a smaller area. The thinner blades of the new scrapers can also be bent or sprung slightly to conform to different surfaces, so it's possible to reach into a slight concave without the corners digging or even conform to a slight convex shape. All my best scrapers used to have the Sandvik trademark stamped on them, but the new Bahco scrapers are the same brand with a different name. |

To comment on Duckworks articles, please visit one of the following:

|

|