I am from Poland living in Ireland. When I first saw a photo of the ''oru'' kayak built from Coroplast, I thought that this is a brilliant solution and material. Unfortunately, the project had two disadvantages: first, I do not like kayaks (I prefer canoes), and second the price.

So I have begun searching the web for a project for me. I found the designs Ken Simpson, and that was it! The projects were easy to make and they looked nice and practical.

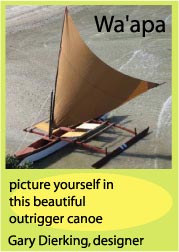

I chose a design by Ken Simpson by looks, not reason. Designs by Ken I like. A better design would be probably be a PD racer, easier to do and with a flat transom mounting the rudder would be simple, but I always liked boats with pointed stern, and above all, it was supposed to be CANOE!

The first attempt to do sails was not successful. I wanted to sew an old tent, but my sewing machine did not want to sew through the material. The current sail is not sewn and I've done it with the cheapest tarpaulin and cut to the shape of the lugsail. The edge was cut down, wrapped and secured with rivets. The mast is a 3m steel tube and the boom and yard is a thin bamboo beam connected by a cable tie.

Tools and materials used to build it are most often are found in every home. Pencil, ruler, wallpaper knife, screwdriver and drill. The only rarer tool is the instrument for crimping space corners. I've done it with large washers screwed to the handle so that it can move around as you press the material.

For joining folds on the hull, I used bolts and nuts with big washers, because I planned to make the hull permanent and not folding. Some elements are held by cable tie, and some stuck (heel of the mast and stiffening the sides) I used polyurethane glue ''Gorilla glue''. Of course, duck tape is indispensable to build a duck boat.

Quickly, I learnt where to buy this material. In Ireland it is called corrugated plastic sheets' and for 35 euros I became owner of 10 'x 5', 6 mm thick sheet. Material from which I've done hull has different names in different countries, ''Coroplast'' in America, "Corflute'' Australia, ''Corugated Plastic sheets '' in Ireland, ''Tekpol'' in Poland, etc. The best way to find it is to look for some ads and see what it is called. Most of the projects recommended 4mm but I used 6mm and if I did it again today I would use 9mm - greater stiffness and resistance.

My material was about 2 feet longer than the project by Ken, but I cut off one foot, and used it to stiffen the sides.

I began by drawing the folds, then the help of slats and special tool broke the material along the drawn lines.

All edges are sealed with duct tape.

Folding on the lines and gluing the sides. Once you have the overall shape I used screws and washers.

I planned to do a canoe, but when I saw the resulting shape of the hull, I decided to make a sailboat. The front struts tightened the tube which is inserted and the mast is made of steel tube, diameter of 30mm.

The paddle is the rudder, but with stronger winds becomes problematic. I made rudder supported legs. After the first capsize, I added buoyancy in the bow and stern as well as on the sides.

My boat all the time is changing and I constantly add new modifications which amuses me as much as using it.

My Sailing boat is small, 2.9m long, so even in strong winds it is not fast. It is rather narrow so no standing up. For these reasons I use it on inland waters - (no full deck hardly encourages trips to the sea). It is hard to use it for more than 3 hours and it gets uncomfortable. Sailing depends also on the strength of the wind, and reefing can only be done to a point. It was a fun project, more a toy than a serious sailing boat but it used my imagination which I love.

|