Custom Search

|

| boat plans |

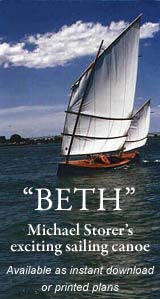

| canoe/kayak |

| electrical |

| epoxy/supplies |

| fasteners |

| gear |

| gift certificates |

| hardware |

| hatches/deckplates |

| media |

| paint/varnish |

| rope/line |

| rowing/sculling |

| sailmaking |

| sails |

| tools |

| join |

| home |

| indexes |

| classifieds |

| calendar |

| archives |

| about |

| links |

| Join Duckworks Get free newsletter CLICK HERE |

|

|

| Flywood |

by

Mario Stoltz

- Hamburg - Germany |

Recap from last article which was before the winter break, well, the extended winter, spring and early summer break. I had started a Flo-Mo Flywood one-sheet canoe in the last warm days of late autumn. As I can only build outside, my progress was stopped when temperatures dropped below 10°C ambient temps and when the wet season started. Looking back at the metadata of the pictures, I find that this last day amazingly was 11 November 2015. November! Kinda scary. Talking about weather, anyone know this page? The last report stopped with butt joining the parts to form full-length flat halves. Actually, I did get further than that, but I was a bit frustrated and hence did not want to report before I knew how to fix my mistakes.

After more drilling and much more zipping, I dry joined the two halves to form the full 3D shape. Here, it is apparent that both ends (but one much more than the other) are fundamentally flawed the way I built them. The spot where the chine merges into the twisted bow seems to be much too far away from the stem. Maybe the plywood intended in the original design had different mechanical properties. Hence, the bow is plopped inwards. I tried for a while to get it to pop out by pressing from the inside, but only to the result of ripping a few zip ties of the keel curve and myself cursing.

An interesting find, was that the spot where the chine merges into the bow/stern is not actually subject to any noticeable stresses. I was expecting that it is a potential crack point, but that is far from the case. All tensions created by the chine are spread outwards and find themselves in the keel joint. I could well have spared those reinforcing patches I spent so much thought on. The idea for these came from a very old Duckworks article which had a photo where I saw such patches and thought them a good idea. What I ended up doing was taking out the thin pull saw and taking the chine cuts much closer to the stem/stern. This fixed my issue quickly.

With all the trying to get the bow to pop out, breaking and re-setting zip ties, I ended up flipping the hull a few times too many and laying it on the port or starboard side. At some point here - to my despair - one of my top panel butt joints gave in and simply snapped. Remember, I had been cheap here in that I had reinforced them with a layer of drywall tape - not woven glass tape - inside and out only. This stuff apparently is not as crack resistant. I had initially figured that this would not make a difference, as the gunwales will be reinforced with two layers of laminated batten. As I painfully noticed, I was wrong and it did very well matter, especially as the battens were not yet present at this stage *sigh*. I also learned that the edges of the broken joint were in fact sharp - the red stuff near the emergency batten is blood. It was really difficult to pull this butt joint back together, because I had nothing to hold against. Try pulling a butt joint in a 3D shape together under tension (the X direction), while also aligning it in Y direction, then holding like this, somehow, and fixing it with clamps, all with only two hands. More cursing. In the end, I made it with only about 3mm (1/8 in) error in X and Y direction, which I considered acceptable for my standards. Next steps: 1) fix the broken butt joint in epoxy, 2) spread the hull to final width with right-sized spacers measured from my paper model, 3) make "tack welds" along the chines and keel joints with thickened epoxy, 4) remove all zip ties, 5) finish chine and keel joints with more thickened epoxy, wet lay a stripe of glass tape on the inside of each joint, 6) laminate gunwales in place, 7) fill and shape outside of chines and lay glass tape (certainly not drywall) on the outside of each joint, 8) glass the entire hull. Where I am unsure yet is, should I glass the hull before laminating the gunwales? Probably yes, huh? (Now hold reading for a few seconds and fast forward through autumn, winter, spring and early summer.) It is now mid late July and my wife and kids are out for several days, so I can go ahead unrestricted by any family affairs. Also, the weather is stable - as I do not have an enclosed building space, I must rely on stable warm and dry conditions outside. While I reconsidered the project over time, decided to continue by scarfing the gunwale battens first. I am using two sizes: a smaller 1cm x 2 cm (approx 1/2" x 1") inside, and a 1cm x 3cm (approx 1/2" x 1 1/2") outside, so I will have a grabbing rail. In fact, the aluminium angle was a godsend. The ideal pattern for packing and clamping the parts for the glue upprocess. I separated all layers of the gluing stack with transparent plastic foil (made from cut-up punched pockets/sheet protectors). i glued with ample epoxy thickened with glass balloons. For clamping up the pack, I used more aluminium profiles that I had laying around. After a day, I opened the packet and removed the burrs that had formed between the separation sheets from the squeeze-out. These went away OK with a sharp wood chisel. Afterwards, I ground the epoxy from the flat surfaces - those that were to be glued later - with a small triangle sander with an 80-grit pad. Overall, scarfing the battens worked perfectly, they felt like a single piece and were fully flexible across the joint.

Now there was no more excuse to keep the hull in the basement. After my experience from autumn with the snapped butt joint, I knew I must support my hull in a more flexible way. I improvised two building cradles by stapling short loops (3ft or so) of webbing belt across two standard wood racks each. This worked just fine for the boat, although working height was way too low for me. I would have needed them at least 2ft higher up to reduce the strain on my back. Well next time... The hull as I left it last November was still very wobbly - not surprising for unsupported 4mm ply. Also, the shape was purely arbitrary. In autumn, I had put in five spreader pieces, but these had random widths and were there only to keep the hull from flopping around uncontrolled and collapsing to flat again. So, as first activity on this day I took out my trusty paper model and copied a few width measurements to the full scale hull. Scaling factor was about 9.45x, which meant caution with errors. Started with five spreaders again, but now of the correct width (or what looked like it copied from the paper model). Next I dry fitted the first layer of gunwale battens with spring clamps. Amazing how this increased the stiffness of the hull already. For the first time I was starting to believe that this boat may eventually work out fine despite my low quality workmanship. I also noticed that two of my five hull spreaders did not seem to make sense - they seemed to pull the gunwales in where it should be further out, so I simply removed them and the shape looked better. Next, I ground those areas of the hull surface that had epoxy where the gunwales will get on - one butt joint zone per side. Short work again for the triangle grinder with 80 grit pads. I glued the battens on with national brand "waterproof" wood glue. Drying time is nominally "at least 1hr" - I allowed 1.5hr - it was a very hot day, so I deemed that sufficient. Due to the limited number of my spring clamps, I glued the battens on side after side, so in four steps over about 6hrs. Note to self: get 20 more spring clamps. Or more. After both layers of gunwale were attached on both sides, the hull shape felt very stable, highly satisfying.

Next on my task list was to get the zip ties replaced with epoxy globs ("tack welds") to prepare the inside fillets. About this time of day - a random coincidence - I had decided to empty the little dust bag on the side of my belt sander. The content of this bag looked amazingly fine and dusty to me, so I got into creative/experimental mode and thought this would make for great epoxy filler material. Am I hearing a few sighs from the audience? Well. i mixed a batch and stirred in the magic sander powder. Hmm, interesting color. A bit like sheep droppings? But the texture felt smooth enough, so I would give it a try nevertheless. I used the "cake topping bag" method of applying the thickened epoxy, a method I use a lot for baking, and am therefore fairly familiar with. After a while, I noticed that the magic sander powder must contain way more fibers than I was expecting. Actually, what I was pressing out of the bag felt and looked a lot like green herb pesto (you know - the olive-oil/herb/parmesan-cheese/pine-nut paste you can put on spaghetti). Probably not good? Well these are only the tack welds, so just press on. The quantity was OK - I could get spots of my pesto putty everywhere where it mattered. Trying to model it into shape was nearly impossible. Upon touching any of the tack welds with a stick/depressor/round shape cut from a wine bottle cork (tried all these), the putty wanted to magnetically jump to the tool rather than stick with the plywood panel joint. Filler fibers just sprang out of the mixture and there was no way to really get the surface smooth. Sorry I do not have a good photo - you can just guess the pesto putty on the inner seam here:

In retrospect, I probably should have tried to paint the tack welds flat with unthickened epoxy - maybe that would have worked better. One evening later (a Monday after work, with only two more evenings to go before my wife would be back) I got around to finally pull those zip ties for good, and epoxy everything over. Actually, this was my debut in doing any major epoxy job *shudder*. Fortunately, all of the zip ties were easy to get out to start with, with the exception of the foremost and aftmost ones - those that sat in the narrow inside fold of the bow and stern. A bit of prying with a chisel fixed those as well. The one good thing about the pesto putty was that it had not flowed anywhere at all, and hence could not glue any ties up. To my mild surprise, the hull did not actually fall to pieces after I had all of them out. Possibly this was due to my belt-style hull cradles, which worked quite nicely so far. What went well: a) had purchased a big box of single-use nitril gloves when they jumped across my path b) knew how to remove small epoxy stains from skin (acetic acid = vinegar; generous use of dishwashing liquid) and understood the health risks = knew that even small stains must be removed from skin immediately c) lots of good reading materials on Duckworks Magazine and elsewhere (e.g. Gougeon Brothers) to learn the how-to, and the pros and cons of various methods d) had disposable mixing pots, sticks and brushes ready and set up. What could have gone better = "cultural learnings for benefit of self": 1) keep wastebin open and accessible at all times 2) devise more reliable method to strip off single use nitril gloves without accidentally touching skin 3) have skin powder ready to make it easier to put on new gloves 4) devise epoxy preparation zone closer to work area 5) a classic: I have read it multiple times and it really was true - cut fiberglass tape to size before starting any wet epoxy work 6) thixotropic agent is so much cooler stuff than micro balloons 7) have stack of rugged dry wipes in an accessible place 8) mixing by weight does not work well in small batches due to viscosity of components that causes balance to show final weight later than normal 9) learn how to estimate the correct quantity of filler for the thickened part of the epoxy job, as I played this purely by ear this time.

Stay tuned for the next installment... |

To comment on Duckworks articles, please visit one of the following:

|

|