|

Steve and I were out the other afternoon at just about sunset and took a picture of each other. If it's a beautiful afternoon we usually jump in Helen Marie and race him home just to have an excuse to go out on the water. Both of these boats are so easy to use that it's nothing to get in and go at a moments notice; about like getting in your car and going.

This is what it looks like on his other side.

Helen and I took the dogs out on the big river, the Manatee, last week to have dinner at our favorite water front place, they have protected floating docks and are dog friendly. It's fun to go into the tight little harbor and show off how well Helen Marie handles, she'll turn in her own length. It was a full moon on a clear night, hard to beat this. Our son Jamie was having a similar experience in front of his house in Utah; well at least we both had the same full moon.

There has been a whole lot of interest in building these simple light foam boats I've been talking a boat; so much in fact that the things are sprouting like mushrooms here at the shop. I'll attempt to show you how it's done and how much fun it is. My goal was to make a 14 foot kayak that was light enough to wear as a hat, be extremely stable so I'm comfortable at all times and be indestructible in the extreme, as in throw it in the swamp for a year then pull it out and have it be in the same condition as it went in. We're even thinking about building a full size boat using this same "stacked" foam method. Imagine a 16 foot Melonseed that's solid foam except for the cockpit and it won't weigh anything cause it's basically made out of white air.

|

This is one I did last week, it's all glassed and painted and still only weights about 20 pounds, center console and all. It's 14 feet long. There's only one layer of six ounce cloth covering the foam but that's all you need; the boat is solid foam, there are no open places under the decks. I did drop this one on the sharp edge of a ladder and poked a hole through the glass and dented the foam under. I just mixed up a little thick epoxy and filled it up, stronger than ever. This one floats in about a half inch of water even with my fat bum in it. You can put it side ways to the shore and step in without getting your feet wet and it's floating.

|

These things have even attracted the attention of some "real" boat builders and they don't get any realer than these two; here's me talking to Charlie Morgan and Tim Horsman. It just seemed to be too simple to be for real so they had to see for themselves. I think it's the extreme light weight and being impossible to sink that interested these two, and they did bring beer, lots of it.

|

|

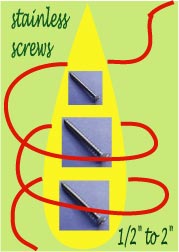

Helen said that we really need a bigger one for the two of us plus Cessna and Tuck dog so here I go on a 16 footer. It doesn't take much to get me started on one of these. You get this 2 inch thick foam at Home Depot for under $20 for a 4 x 8 piece so that cost is nothing, this boat took 4 pieces. You just draw out your basic shape and cut it with a jig saw, it's like cutting air. This one is stacked four layers high plus a "doughnut" on top. You don't have to use full pieces of foam for everything, you can piece it all together with the scraps, just spread the joints out. It took me about three hours to lay out and cut these pieces. After you have all the pieces cut to a half way good fit you need to stick them all together, if you were smart you will have labeled each piece. You're not going to believe this next part but I swear it's true; it took me 10 minutes to glue the whole thing together. I started and finished before Stan could drink a beer. I put a 2 inch piece of foam under the ends to get some rocker. To glue them together I just dab little dots of PL Premium 3X all around about 6 inches apart and jab in bamboo skewers you get at the grocery store to hold them together, don't let the glue come out to the edge or it'll be hard to get a good sand edge. Anything harder than the foam screws you up. This glue holds it all together till you glass it. This is the best glue we've found to use, we've tried lots of others including the "foam" adhesives. It comes in caulking gun tubes for about $4 each.

|

|

Beware, lots of things melt this foam; spray paint, paint thinner, alcohol, bondo, other types of resins. Spackling doesn't seem to like to dry when used as a quick and easy filler. Anything hard at the surface will screw up the sanding. Fairing and sanding is fun and easy and your sand paper never wears out. Glassing is the same as always, messy and picky only this time you have to do an extra good job because sanding the rough edges may cause you to go right through the foam next to it.

|

|

Here it is all smooth and glassed with a couple layers of epoxy on, I added some blue tint to better see what I was doing. After I put the seats in and took some measurements I realized that it's not long enough for us and the dogs so I took the saw and cut it in half and added a foot, no big deal and it'll actually be stronger than before because of the overlaps with the new glass. There was a visitor standing there watching when I cut it and I thought he was going to faint. Now it's a 17 foot double kayak.

|

|

|

|

Here it is about finished except for the center consoles, I'll put them in tomorrow. The boat without the seats weighted about 20 pounds, these super seats added another five pounds each but I think they'll be worth it, they fold down and are really comfortable which is what may get me out in it. Yes the paint is still house paint, gloss exterior for all of the boats. The new acrylic paints are really good, we've had some of it under water for months and months with no ill effects. I don't know if it matters but I like Sherman Williams.

|

|

While I was doing the big double a girl showed up with Stan, took one of the other foam boats out and immediately had to have one. She had never been in a kayak in her life. We don't normally let people, especially strangers come and work in the shop (in fact, never) but when she said that she was from Montana and didn't know anything about boats or water or anything and had never even seen fiberglass we figured she would be perfect for some good entertainment. And she had beer. She had to be out in a week, finished or not. Don't forget our motto, "Your Catastrophe is Our Entertainment". That comes right in front of "We don't do stuff if it ain't fun".

Much to our surprise Tana knocked this one out in four days. She was no fun at all, didn't screw up a single time. She wanted a big 16 foot single to handle her dog and coolers and such. She did it 100% by herself with only a little instruction from me; she especially enjoyed shaping the hull form.

Then Stan said "hell I think I'll make one only this will be a wider stand up, sit down self draining all round fun thing" and here it is. Now we all have to do one like this only make it look like an alligator or dolphin or something.

All of these foam boats you see here didn't exist 7 days ago, that's how easy they are to make. They cost about $125 in materials; 5 or 6 yards of glass cloth and about a gallon and a half of epoxy does it. Remember that when your shop/garage is totally filled up with a zillion little foam particles all you have to do is open the door and blow it all out into your neighbors grass.

|