|

Folding Kayak

( Including complete plans and

instructions)

My friend Bob Williams built one of these folding kayaks from

plans that were printed in Popular Mechanics about forty years ago. It was also

published in Boy's Life and Field and Stream. He bought a reprint

from a magazine in 1978, and has had the plans ever since. After twenty two years

the boat came to be built in kind of a curious way.

Bob was interested in a houseboat that Rags Ragsdale of Florence

Oregon had built and later written up in Messing About In Boats. He called

Rags to talk about it, and during the course of the conversation, happened to mention the

folding kayak. Mr. Ragsdale then informed Bob that he, Rags, had bought the very

first set of plans from the original designer, Robert Romaneck. Rags went on to

reveal that he had built over fifty of the things, and was very enthusiastic about the

design. Bob could not help but catch some of that excitement, and the rest is

history.

Here I am at the helm of this stable and fun little boat.

|

Bob called me up the other day and invited me to accompany him on the

christening and maiden voyage of this new folding kayak. We took her down to the

Guadalupe river near his home in Kerrville, Texas, and after unfolding the boat, each

enjoyed a brief cruise.

|

Assembly is easy

|

Unfold

|

Pop in spreaders

|

Drop in the seat

|

Pick up (only 40 lbs.)

|

:Launch

|

| What follows are the photos, diagrams and

instructions as they apeared in the original Popular Mechanics' article |

It floats!

|

NOTE: I should mention that Bob built his

folding kayak 12 feet long rather than the specified 10. |

| Click

here for a zipped version of the plans: thanks to Bryant Owen

Folding Kayak

By Jess E. Rathbun

It’s not fast, it’s not roomy and you won’t find many practical

uses for such an outlandish craft. In fact, this center-folding kayak has only one feature

to recommend it. It’s fun. At $15 apiece, you can afford to make one for every member

of the family. And you can tote a whole folded fleet on top of your car.

Construction is also unorthodox. Instead of using screws, nails or other common

fasteners, you "tape" the boat together with canvas and contact cement. No metal

parts are required. |

Materials

List |

| Plywood (Exterior

grade AA or AB) |

| 1 pc. |

1/4" x 4' x 10' |

Body panels |

| 1 pc. |

1/4" x 9" x 4' |

Floor board |

| 1 pc. |

1/4" x 9" x 14" |

Back rest |

| 2 pcs. |

1/4" x 8" x 15" |

Paddle blades |

| 2 pcs. |

1/2" x 1' x 2' |

Spreader boards |

| Lumber (All hardwood) |

| 2 pcs. |

1/4" x 1/2" x 6' |

Inside strips |

| 2 pcs. |

1/4" x 1/2" x 10' |

Outside skid strips |

| 1 pc. |

1" x 6' dowel |

Paddle bar |

| Misc. |

|

|

| 24-ft. strip of canvas 2-1/2 in.

wide, cut on bias |

| 17-ft. strip of canvas 10 in. wide |

| 1 qt. contact cement |

| Finishing materials (waterproofer,

paint, etc.) |

Built according to the specifications included here, the kayak will weigh only

about 40 lbs. And will accommodate an average-sized man. However, as long as the correct

proportions are maintained, you can shrink the dimensions to turn out a midget version or

increase them slightly to gain a little more leg room.While marine

plywood may be used for the side panels, exterior grade AA (or even AB) will do just as

well here. Canvas can be anywhere between 14 and 18-oz. weight, but should have a tight,

close weave for easy waterproofing.

|

Begin construction by cutting the four side panels from a 4 x 10-ft. sheet of

¼-in. plywood. All these panels have the same outline, the only difference between the

top and bottom pair being the cockpit cutouts. If you’re planning to make two or

three kayaks, cut the required number of panels at one time so that you can use the first

two as patterns. The rounded ends of each panel are squared off slightly to present a 1 ½

-in. straight edge so that the canvas will go around from top to bottom without wrinkling.Next,

cement the ¼ x ½ -in. inside strips and retainers to the panels, positioning them flush

to the edge with the ½ -in. face down. The strips are designed to provide reinforcement

for the seat bottom-floor board, but also to form notches to hold the spreader boards.

Taper the ends of these strips and the inner retainers so that you can remove and insert

the spreaders easily. Outer retainers act as stop blocks and need not be tapered.

Once these are in place, paint the inner surfaces of the panels since they will

be almost inaccessible once the boat is assembled. Be careful to keep paint off the

outside surfaces for this will prevent the contact cement from adhering well. |

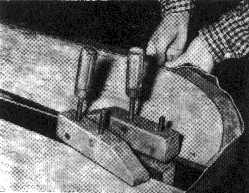

| To assemble, position top panels on bottom panels. Then, using clamps and a

spacer block at teach end, mount the right-hand pair 3 ½ in. from the left, as shown in

the photo on the opposite page. You’ll have to cut the canvas edging strip at a

45-degree angle to the weave to provide the necessary stretch so that it will fit around

curves without wrinkling. Apply cement to both wood and canvas surfaces, but do not cement

the canvas which stretches across the gap between the two pairs of panels since this will

stiffen it. |

CLAMPS AND SPACER

block are used to position the two pairs of panels the correct distance apart so that the

2 ½ -in. strip of canvas edging can be applied. |

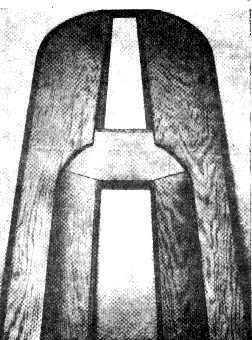

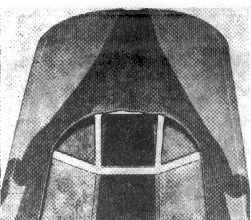

INSTALL

SPREADERS after "taping" edges of panels. These should be trimmed for a proper

fit before the center gap is covered with canvas. Allow enough slack so that spreader may

be removed for folding.

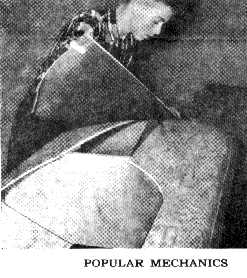

COVERING GAP between the right and left pairs of panels is the last

step before finishing the hull. Allow 2 in. extra at cockpit and fold it underneath.

|

CUTTING OUT

portions of the spreader will lighten it without reducing strength to the critical point.

Note alligator treatment used to decorate the hull. CUTTING OUT

portions of the spreader will lighten it without reducing strength to the critical point.

Note alligator treatment used to decorate the hull.

|

| To apply the canvas edging, hold one end flat against the edges of the plywood

and stretch it. Then, while it is stretched, fold the sides of the strip over both top and

bottom panels at the same time. Do a short section at a time, overlapping joints in the

canvas about 2 in. (Try a practice session with scrap plywood before attempting it on the

boat itself.) After edging is complete, pound the cemented surfaces with a block of wood

and hammer or mallet to insure a good joint, then let the cement set overnight before

inserting the spreader boards. Next, cut the spreader boards, check the

fit and trim if necessary. However, keep in mind that there will have to be a certain

amount of slack in order to remove the spreader boards easily. With the spreaders in

place, cover the center gap with canvas, then remove the spreaders and cement the skid

strips to the bottom. After making the seat and the double-blade paddles, waterproof the

canvas and paint all wood parts. |

Here is the letter we got from Popular Mechanix

giving us permission to publish the article above

From: Joseph Oldham

12/02/99 09:38 AM

To: Duckworks Magazine

Subject: Re: OK to reprint?

All editorial material is copyrighted by us. So technically, you cannot use any of

our material without our written permission. But since the plans are not currently

available, I will give you permission to use the plans on your website for now. If

the situation changes, and we are thinking about reissuing many of our old plans, you may

have to remove the plans at some future date. Thanks for inquiring.

Joe Oldham |

|