|

It floats ... and it rows quite nicely, even with last-minute homemade

oars. I just had to get the news out. |

| Yesterday was a beautiful crisp

Fall day in Sacramento. A perfect day for joining the ranks and acquiring the title of

"amateur boat builder." My son and I, with minimal fanfare and after a couple of

quick pictures, loaded PS#1 into the back of ol' WT (my Weekend Truck), drove to his house

and picked up his son, Christopher (it's his boat, but he did not know it yet). We drove

directly to Nimbus Lake in Folsom and arrived at my favorite launch site, a somewhat

secluded county property with a shallow-angle gravel ramp, two outhouses and a small

parking lot. |

No trailer needed for this one.

The Pointy Skiff fits with room to spare. The lift gate even closes. I can even slide the

boat in and out without help.

|

Christopher is now told the good news:

"I have a surprise for you….this is your boat, not Papa’s." Notice how

the builder took advantage of the gap in the inwale (better known as lack of advance

planning) with a non-traditional cleat installation. Hey, it works.

|

We dragged out the boat and plopped

it into about 6" of water. Empty, it bobbed in the calm water with both stern and bow

slightly off the lake surface... IT FLOATS! Securely

captured inside his life jacket, Chistopher jumped into the boat. He had earlier decided

that Papa's boat should be named "Sea Lion" if it floats, and "Fish"

if it doesn't. He has an unusual sense of humor. At this point, I told him that this was really his boat and he

could name it anything he wanted. After the look of disbelief disappeared from his face,

he jumped up throwing his hands in the air while grinning as only a 6-year old can. |

| "SEA LION" and its new

owner were launched. I shoved ‘em off with my son, David, and Captain Christopher as

the only passengers. I wanted more pictures, so Dave rowed it around in a large circle

about 20 yards off shore. Christopher was already giving orders from the stern seat. With

no fishing poles along, Capt. Christopher decided that exploring and duck watching were

the things to do. |

It floats! It floats flat, too.

Christopher is kneeling on the seat and leaning out over the rail behind his dad. BTW, the

oars worked great. The next ones will be made with ½" ply blades.

|

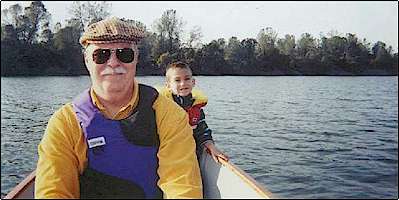

Dad and new owner in the stern. You

can just see the bow about 2" clear of the surface. The boat rows effortlessly. It

must be the custom oars. Meanwhile, I’m stuck on shore taking pictures. When is it my

turn?

|

At this point, watching the two of

them in this little red boat with it’s ugly oars, I knew I had helped create a

childhood memory that will outlast both his dad and me. Not a bad return on my investment

of making a little wooden boat. |

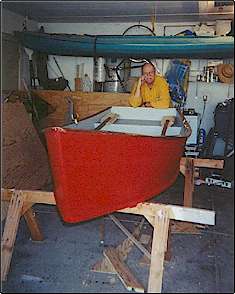

Pre-launch

celebration. You can see we are not big on festivities and fanfare. Check out the

custom-made oars; genuine scrap redwood and gusset reinforced ¼" ply. I

especially like the imported "leathers"(made in China duct tape) Hey, it works.

Eventually, an electric trolling motor will be the primary propulsion. The bow and stern

seat screws were not counter-sunk so we can easily remove them and lift off the seat

tops. I can’t remember who built the PS with an electric battery stowed in the

bow seat with the cable running aft through PVC conduit to a plug in the stern seat.

Thanks for the great idea and we are going to use it when the motor is purchased. |

|

These

two seats are presently stuffed with cut to fit foam insulation. The boat’s finish

consists of two coats of epoxy, two coats Home Depot latex primer, two coats of HD

porch/deck paint. Each epoxy coat and paint coat was lightly sanded. The red paint is the

pits; glad it doesn’t show in these pics. I splurged on the gunwale and inwale:

¾" Philippine Mahogany with three coats of cheap marine high gloss varnish. |

My Turn to Row With Dave in the stern and Captain

Christopher in the bow taking pictures with his grandmother's disposable camera, we shoved

off again and headed for "open water." Good thing this isn't a sailboat -- dead

calm. I was somewhat disappointed that we didn't have a bit of wind and waves. Maybe next

time. |

| With slightly less than 500 pounds of people on

board, Sea Lion's bow and stern settled into the water with more than sufficient

freeboard. It rowed straight and turned on a dime giving about 5 cents' change. If this

boat will handle a 2-foot swell and over-powered motor boat wakes, we will have a serious

fishing craft. (There's this Salmon River in Oregon where Dave and Captain Christopher

fish.) |

The builder finally gets a chance to

row. This also verifies that three people do fit, but it's crowded. We have about 485# of

people on board. The boat lost about 3" of freeboard. In other words, the bow and

stern are in the water. It still rows effortlessly. No wind or waves. Maybe next time I

can really test it out.

|

| Dave stood up and did a pretend cast. SEA LION

hardly rocked. I like this boat. Size limits its people/gear capacity: two adults, or one

6-year old Captain and his dad or Papa, is max for comfort, especially since the male

adults in this family are all over 6' and 200#.

SOMEONE PLEASE TELL PHIL BOLGER THAT HE DESIGNED A REALLY WICKED GOOD BOAT. Damage Control. |

|

The rowing seat separated from its

frame on the forward end, starboard side. No big deal, but I will use glue and screws to

repair it. The hull paint is awful; we will sand and use a proper paint for that repair --

Interlux epoxy or something similar for a lasting coat.. It was a great

launch. Oh, the oars? I'm ordering them this week.

Jim C |

| NOTE: Christopher's boat is the first of three

10.5' boats I'm building for each of my fishing grandchildren. The boat was designed by

Phillip Bolger, a naval architech in Glouster, MA. His name for the design is "Pointy

Skiff". I am part of a loosely-organized email group with about 430 international

members. We all build and/or write about Bolger designs - he has done 100's of boats of

all sizes and types.

Sea Lion took about 3 months to

complete. It's built out of 1/4" and 3/8" plywood, epoxy coated with fiberglass

taped joints Marine glue and screws are also used throughout the construction. |

One happy kid! Captain

Christopher in command. I think I better cut down those oar handles a little more. The

smooth seam where the bow seat meets the hull sides is done with exterior painter’s

caulk. Even if we weren’t going to take up the seats for further modifications, I

would still use this. You can make a perfect fillet and it can be removed and re-done

anytime. |

|

![]()